Professional Solutions for Injection Molding in the AI Era

Oct 8 to 15, 2025 – Düsseldorf, Germany Hall 13, Booth B-43

Global manufacturing is shifting. Supply chains must be resilient, sustainability requirements are rising, and markets are more volatile. This calls for precision, efficiency, and adaptability. Industry 4.0 is not only about automation; it is about intelligent, interconnected systems that transform production.

We are shaping this future with two pillars that come together at K-Show 2025: the new DMZ multi-material injection molding series and the iChen™ Smart Family led by the AI Molder. Together, they form the bridge from steel to smart manufacturing and power your future in intelligent molding.

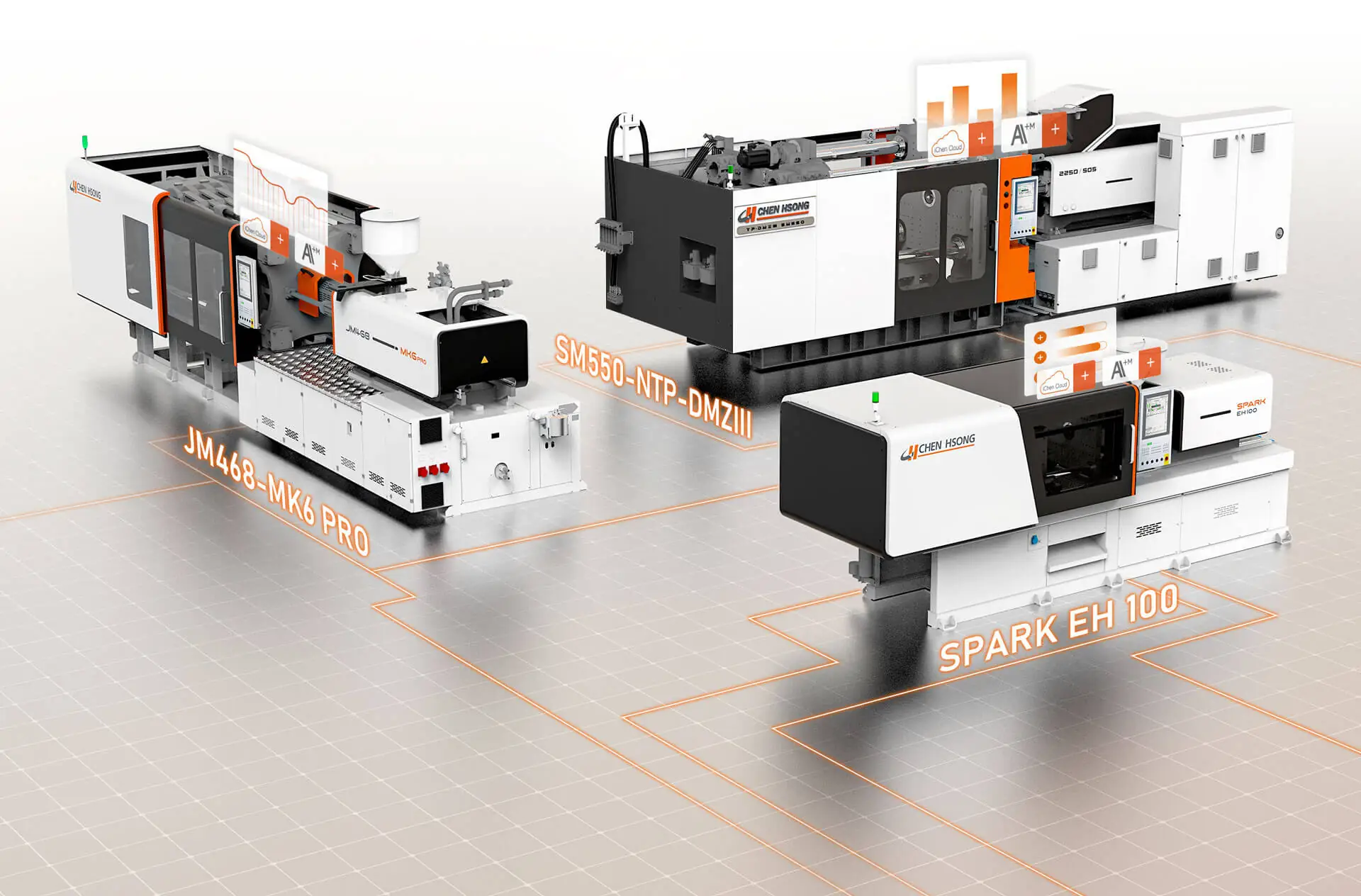

Machines on Display

DMZ · Advanced Multi-Material Molding

We have spent decades refining multi-material molding. DMZ is the next step. It brings a modular frame, a dedicated multi-material control system, and a servo rotary platen that keeps alignment tight and cycles consistent. The result is smooth single-shot production that feels effortless on the floor.

You get fast changeovers, strong part-to-part repeatability, and lower power use. Our independent turntable holds gaps to ≤ 0.15 mm and the closed-loop encoder positions to ± 0.005°. eDrive recovery saves 15 to 30 percent energy, and the servo rotary platen uses less power than hydraulic setups. Use DMZ when colour harmony, soft-touch overmolding, or mixed polymers must line up perfectly.

We will run the SM550-NTP-DMZ III in live multi-material production. Learn more on our K-Show 2025 hub and if your attending don’t forget to book an appointment with one of our experts.

SPARK EH 100 · All-Electric Precision

SPARK first made its K-Show debut in 2019. The All-Electric is back for more and brings precise servo motion, faster cycles, lower energy per part, and a clean, quiet floor.

This year we are bringing SPARK EH, one of the latest models in the family. It pairs all-electric precision on the main axes with hydraulic auxiliaries for wider mold compatibility. You get lower energy per part, lower noise on the floor, and steady quality across shifts.

Powered by four patented 4A technologies: Agile Boost Control (ABC), Auto Stress Release System (ASRS), All Adapt (AA), and AxP with Floating Point Toggle. SPARK delivers precise motion, stable cycles, fast response, and strong efficiency. With advanced controls and high-grade components, it sets a high bar for electric injection molding. Learn more on our K-Show 2025 hub and if your attending don’t forget to book an appointment with one of our experts.

JM468-MK6 PRO · Stable, High-Yield Production

The MK6 series is one of our top-selling series across markets, chosen for steady cycles, easy setup, and broad mold coverage. This allrounder is a dependable workhorse. It combines a rigid frame, tuned kinematics, and smart controls to hold weight, dimension, and finish across long runs. You get quick response when the mold needs it, and calm movement when precision matters most. The MK6 PRO inherits the reliability and stability of the MK6, and adds a next-generation control platform, refined mechanics and hydraulics, and advanced control algorithms for higher precision and faster response.

Learn more on our K-Show 2025 hub and if your attending don’t forget to book an appointment with one of our experts.

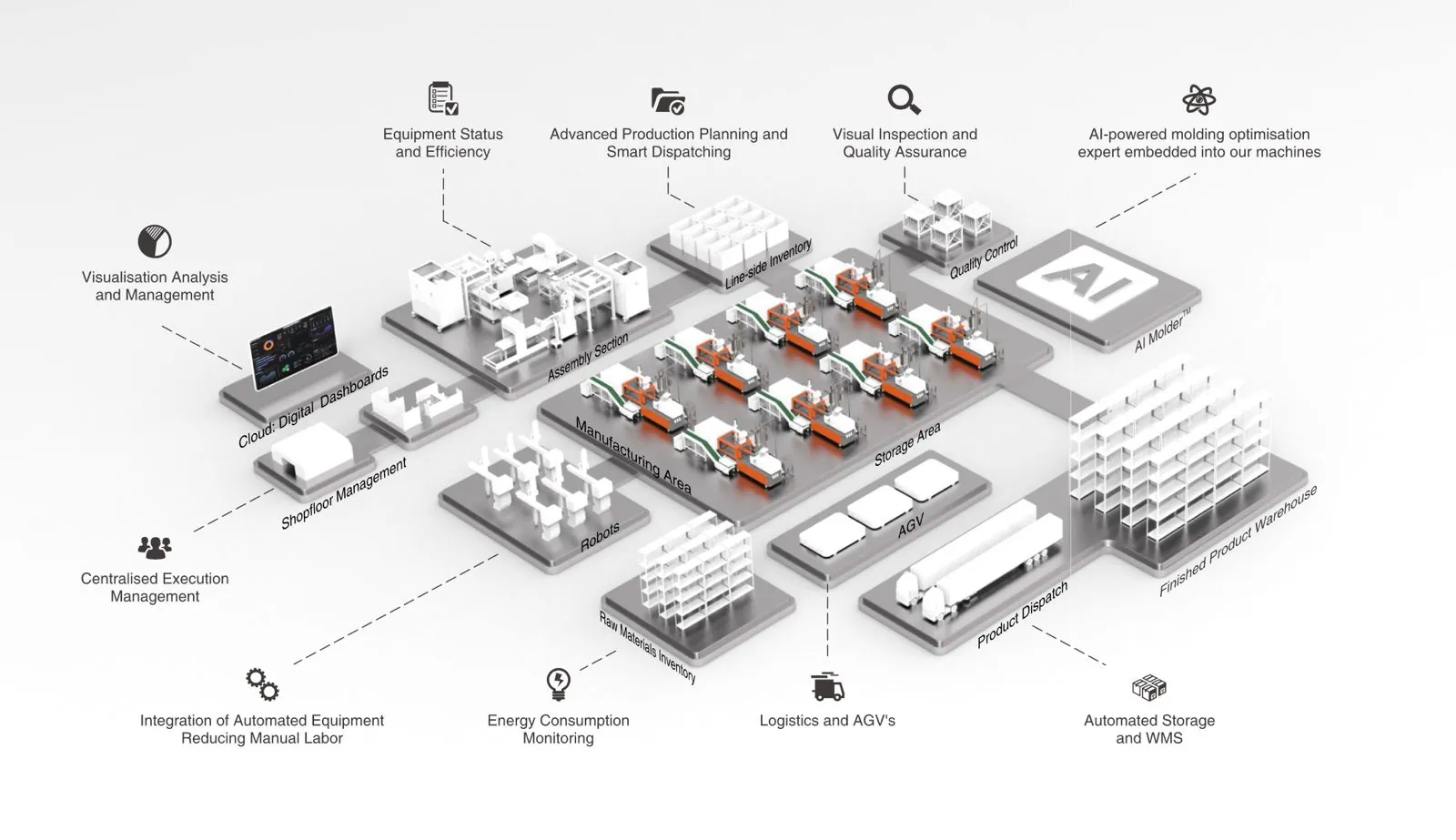

Smarter Manufacturing for 2025 and beyond

The future of manufacturing isn’t just about stronger machines. It’s about smarter factories. In an era defined by speed, sustainability, and digital transformation, success depends on seamless connectivity and intelligent automation. That’s why we created the iChenTM Smart Family. Here is a sneak peak:

iChen™ Smart Factory

Your local control layer for the plant. It gives production managers real-time visibility and direct control on site.

- Shop-floor control: see machine status, energy, and AGV flow in real time

- Execution: dispatch jobs, track quality, and optimise schedules

- Automation: connect robots, storage, logistics, and inspection

- Visualisation: live dashboards for production and QA

iChen™ Cloud

Your enterprise layer for multi-site operations. It links plants, systems, and regions in one coordinated platform.

- Multi-site visibility: monitor output and OEE across factories

- System integration: connect APS, MES, QMS, WMS, and IoT in one data layer

- Planning and scheduling: balance capacity and dispatch work across sites

- Analytics: compare KPIs, watch energy and costs, guide decisions

iChen™ AI Molder

Smart start, precise production. A machine-side assistant that shortens trials, stabilises runs, and keeps quality consistent.

sMolding

- First-parameter calculation from industrial data

- Shorter mold trials and less scrap at start-up

sTroubleshooting

- Fast defect diagnosis based on machine learning and process know-how

- Clear fix suggestions that cut trial and error

sTabMolding

- Continuous parameter optimisation for mass production

- Virtual inspection, drift detection, and early wear alerts

Meet Us at Hall 13, B-43!

This year is about real gains you can measure: shorter trials, higher yield, and clean data from press to cloud. Meet us at K 2025, Hall 13, B-43 to see DMZ, SPARK EH, MK6 PRO, and the iChen Smart Family working together. Book a slot, ask your questions, and leave with a clear next step. See you there! Learn more on our K-Show 2025 hub and if your attending don’t forget to book an appointment with one of our experts.