SUPERMASTER 200 TS

High Speed Double Toggle Machine specifically tailored for thin wall applications.

One of the latest models in the Supermaster series, it’s new improved design delivers higher injection speeds, faster response time, and many more advantages.

01

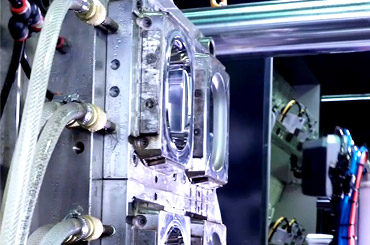

Single Injection Cylinder

Higher Injection Speed | Faster Response Time

0 to 500mm/sec in 0.01 sec

Single cylinder injection design increases the SPEED and RESPONSE TIME of injection. The TS series clearly has an advantage over other two-platen machine manufacturers!

02

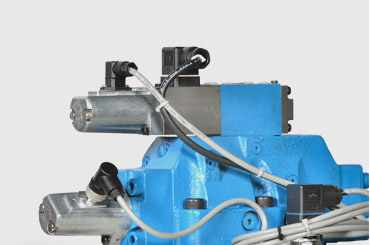

Vickers Servo Valve Closed Loop System

Real-Time Control | Stable System Performance

Real Time Control

High-end Servo Valve completing a closed loop injection control system provides REAL TIME CONTROL of the injection process from start to finish.

This results in stable system performance and premium part quality.

03

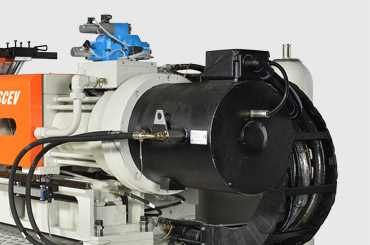

Hydraulic Accumulator

Higher Injection Speeds

Constant supply of oil and pressure on the cylinder as it moves forward! This helps to maintain a consistent material flow, which in turn improves the melt flow through the gates, keeping it at a constant rate.

Consistent Melt Flow | Accurate Shot-weight

The consistent shot weight, combined with higher injection speeds, is a DEFINITE MUST for all thin wall applications.

04

High-torque Direct Drive

Direct Force | Same Axis

True Parallelism

The injection unit is driven by a powerful direct drive in the same axis with NO ADDITIONAL GEARING.

Unlike contemporary gear or belt type setups, the TS series’ high-torque direct drive transmits forces to the screw centrally and directly, in the direction of travel, ensuring better parallelism.

05

5 Seconds per Cycle

Cost Effective | Outstanding Performance

Speed

Higher injection rates, faster response time, servo control. The 200TS delivers outstanding performance and truly is a cost effective highly efficient machine for your applications.

06

B&R APROL Controls

User Friendly | High Scalibility

B&R controls provide a high degree of scalability and ultimate control of your closed loop system.

01

In Mould Labelling IML System

WETEC

Simple design | Easy Operation | Stable production | High efficiency | High Reliability | Flexible application

02

Label Material

Verstraete

High Quality, ECO friendly ,humidity & temperature resistant material

Show Case

>

Thin Wall Container

Margarine Tub & Lid

- Cavity : 2+2

- Product Material : PP

- Product Weight : 32 g

- Cycle Time : 5 sec

Specifications

| Screw Diameter | 46mm |

| Shot Weight (PS) | 321g |

| Injection Pressure | 2,180kg/cm² |

| Injection Speed | 400mm/sec |

| Screw Rotation | 250rpm |

Contact

If you have any question, please contact us !