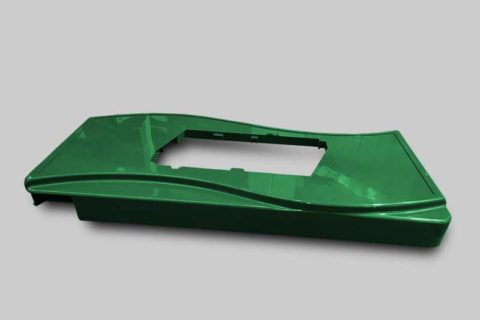

Fan Housing

Plastic Injection Molding of Fan Housings

The Fan Housing (or Casing ) is the structure that contains the impeller; the air (or the fluid) to be handled passes through the housing and it moves toward the ventilation system. In particular, the air in the housing is compressed and, consequently, its speed increases. The performance of the fan depends on the physiognomy of the impeller and on the shape of the fan housing too.

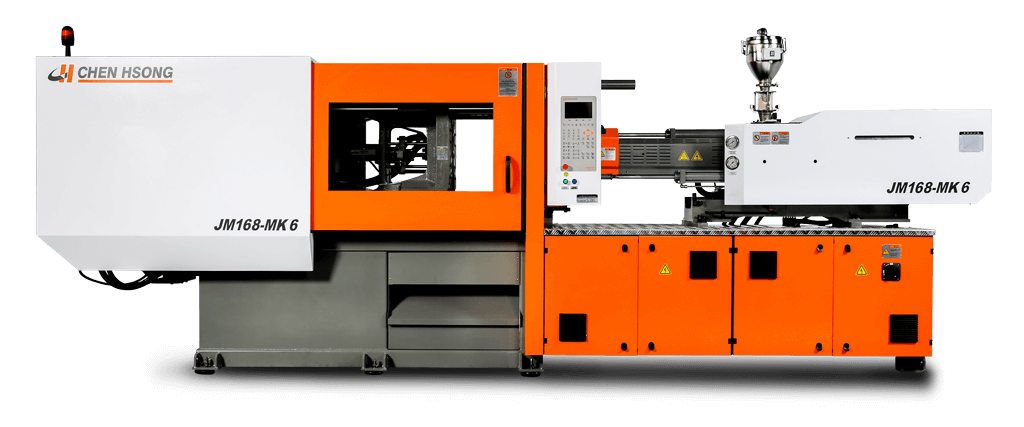

In the above video the JM560-MK6e series of injection molding machines are put to good use manufacturing PP fan housings. The clamping force is 560 tons for a cycle time of 64 seconds per part.

The Mk6 Evolution series is fitted with the CP6.0 controller, and along with the optimized control system and hydraulics, they achieve superior efficiency and overall stability. Chen Hsong’s Evolution series of injection molding machines provide similar performance to the MK6 machines but with a more economical price point. As a result, this can be the perfect match for clients that want to remain competitive whilst maintaining productivity and high product acceptance rates.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: JM560-MK6e

Model: JM560-MK6e

Type: Toggle type

Clamping Force: 560 tons

Controller: CPC6.0

Part Details

Part: Fan Housing

Resin: PP

Cavities: 1

Cycle Time: 64 secs.

Op Mode: Semi-automatic

Other

-

Pickup method: Artificial

Pickup method: Artificial

Share this Case Study