Silicone Lamp

Injection Molding Machine for Producing High-Quality Silicone Lamp

The Silicone Lamp is a popular injection molding application that is manufactured using the SM100-SPARK injection molding machine. This high-quality product is made with a combination of silicone and PC(PBT) resin, which makes it durable and long-lasting. The lamp is available in two cavities and weighs only 7.8g, making it a lightweight and easy-to-handle product.

The manufacturing process of the Silicone Lamp is fully automated, with the SM100-SPARK injection molding machine being controlled by a super high-speed smart computer. The machine has a clamping force of 100 tons, making it efficient and fast. The cycle time for the production of one Silicone Lamp is 105 seconds, which is significantly less than traditional manufacturing processes.

Our client’s factory in Yuyao, China, specialized in the injection molding appliance industry, h industry, and lamp industry. Utilizing ChenHsong advanced technology and machinery, they are able to produce large quantities of the silicone lamp efficiently and consistently, ensuring that each one meets strict quality standards.

Machine Details

Model: SM100-SPARK

Model: SM100-SPARK

Type: Machine reaming machine

Clamping Force: 100 tons

Controller: Super high-speed smart computer

Operator Details

Country: China

Location: Yuyao

Part Details

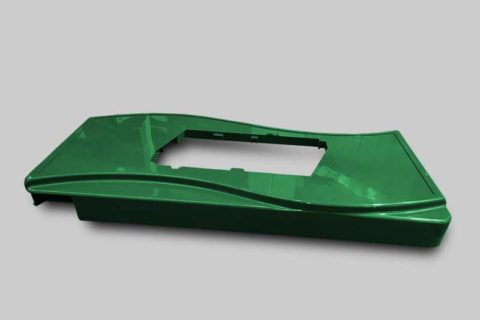

Part: Silicone Lamp

Resin: Silicone +PC(PBT)

Cavities: 1 out 2

Product weight: 7.8 g

Cycle Time: 105 secs

Op Mode: Fully-automatic

Others

- Pickup method: Robotic Arm

Share this Case Study