ChinaPlas 2017 International Rubber and Plastic Exhibition will have its grand opening on 16th May at the Guangzhou China Import and Export Fair (Pazhou Complex), ending on 19th May. This is the largest and most influential international plastics exhibition since K 2016 in Germany!

Chen Hsong will debut seven advanced injection moulding machines at the show from enhancements to popular classical models to brand-new flagship series. They include: the SPEED208, a JM168-MK6, a JM128-MK6, an SM700-TP two platen, an EM180-SVP/3+, an EM150-SVP/3+, and an SM90EJ all-electric. All these represent the Chen Hsong Group’s strength and power in the injection moulding space!

JETMASTER-MK6 Series: Highly Stable and Intelligent

JETMASTER MK6 Series

Although it is not the MK6 series’ completely “new” appearance, we are certain that the two MK6 machines on display will continue to steal the scene.

Light Switch

One 128-ton MK6 and one 168-ton MK6 will form a “production cell” producing parts for electric wall-switches. A fully automated robotic system completes product assembly, quality control and final packaging. Product tolerances are kept to the very high standard of with 0.1mm or less. In addition, the machines are also equipped with the new, highly-intelligent, wide-screen MPC-6.0 computer controller which is ultra-easy to operate!

SPEED208: Precision Hydraulics™ for the speediest, most stable and highest precision applications

SPEED series high speed

As an extension the MK6 series, the SPEED is a super-stable, superb-quality and cost-effective offering. A new and improved anti-locking system and the latest generation of computer controller combine to give fast, fluid, and energy-efficient production of demanding products. Patented Precision Hydraulics™ keeps the machine light, silky-smooth, rock-solid stable and agile. The SPEED is particularly suited for producing packaging and other high-volume products requiring high production speed.

ice-cream cups with IML

During the show, the SPEED208 (208-ton) will be paired with an automatic packaging system to produce 4-cavity, 0.4mm, thin-walled ice-cream cups. The food industry requires high energy-efficiency, clean and environmental production, and raw manufacturing speed, usually with harsh requirements on speed and stability. The SPEED, therefore, delivers superior performance akin to high-end machinery while keeping affordability close to general market ranges. It will not only fulfilling your desire in high-tech exploration, but will also be an amazing experience in itself!

EASYMASTER-SVP/3+: Third Generation, Thrice Better

EASYMASTER SVP/3+

The EM-SVP/3 has been Chen Hsong’s best-selling “classic” product line for many years. Upgraded and enhanced, this product line has now reached its third generation, PLUS more. This time, the familiar “old face” has a whole new set of tricks to show you — like how to produce high-end multi-material over-moulding using two ordinary, “standard” machines!

Power Tool Battery Casing

An EM150-SVP3+ and an EM180-SVP3+ will form an “automated production cell” for two-color automatic over-moulding production of battery enclosures for power tools. Superior repeatability and high stability is required for such a feat, and you’ll be experiencing it first-hand! Whether you’re wondering how to break through current bottlenecks or aspiring to expand your horizon to new possibilities, watching these two machiens at work should provide you with some fresh ideas!

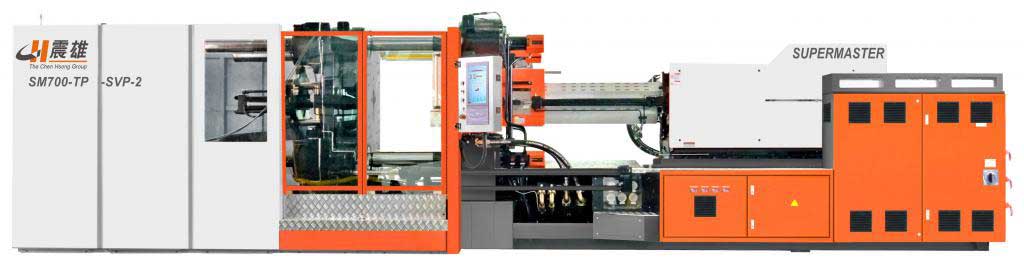

SUPERMASTER-TP Two-Platen: Non-Stop™ Technology

SUPERMASTER TP ADVACNED TWo-Platen

The SM-TP Advanced series of two-platen machines has already made its name in the marketplace as a reliable, trustworthy offering. Only this time, you will find it contains some new “surprises.” The machine on display is equipped with special screw and a highly-precise shot-control system and Precision Hydraulics™. Furthermore, all-digital transducers can automatically identify and adjust mould thickness without operator interference, while its noise-free operation makes the machine super-repeatable. Finally, the display machine is equipped with a quiet, very-efficient electric plasticizing system to give the ultimate product quality and precision.

The biggest highlight, however, is probably Non-Stop™ — a package of patented technologies which, when combined, work with each other to ensure very high stability and reliability, effectively eliminating unscheduled downtime.

Automotive Lamp

The SM700-TP on display will produce 2-cavity automotive lens — an application that has stringent requirements on transparency and dimensional stability, placing very high demands on the injection moulding system. Through its many years of application experience in the automotive sector, and ever-present innovations, Chen Hsong has succeded in producing advanced two-platen machines that meet (and exceed) these demands!

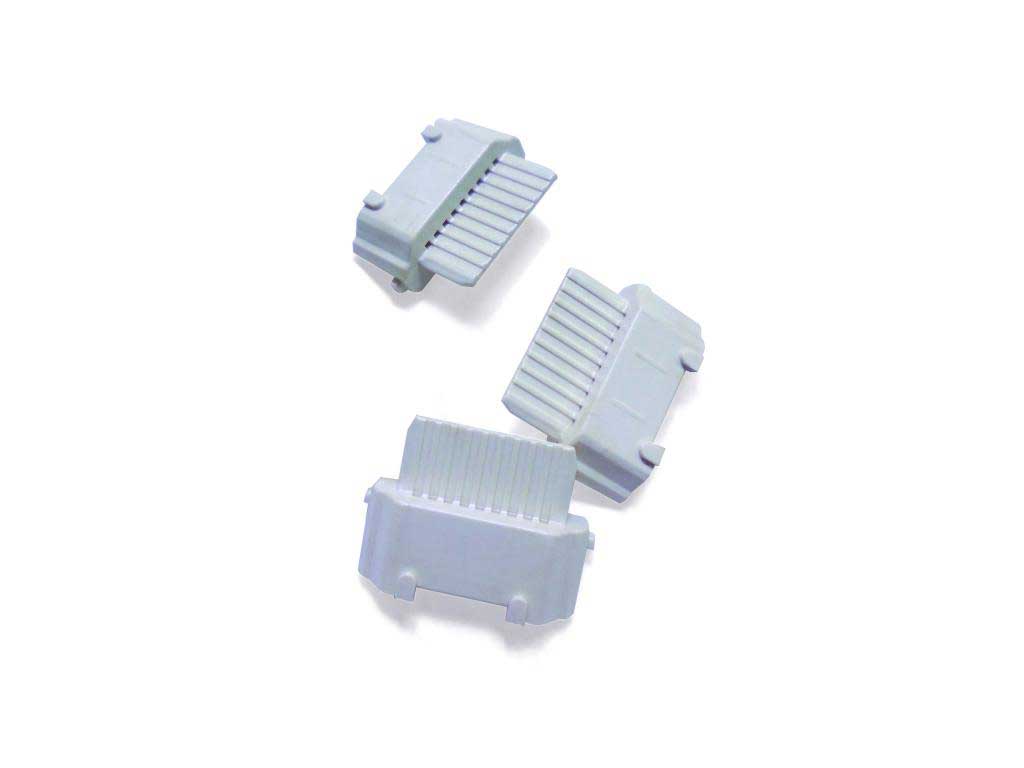

SUPERMASTER 90-EJ: All-Electric Power

SUPERMASTEr ALL-Electric

The SM-EJ series is a brand-new all-electric offering from Chen Hsong. It targets escalating market needs fo for high-quality and cost-effective applications — such as medical, precision electronics, automotive, food and packaging. This is also the best choice for clean-room production.

Electronic Connectors

The SM90EJ (90-ton) on display at the show will produce 8-cavity high-precision electronic connectors. It boasts a unique fast-change system for changing injection unit sizes for ultimate production flexibility. Additional features include high-pressure, high-speed variants. The production cell on display includes an automatic visual inspection module for automated quality control for a one-stop solution to produce high-precision, high-quality, mass-volume parts.

iChen System™ — Your Pathway to Industrie 4.0

iChen System 4.0

Industrie 4.0 has been a popular and unavoidable topic recently among manufacturing circles. However, few notice that real Industrie 4.0 is far from being just automation; in fact, it includes wide concepts such as artificial intelligence in the manufacturing space, flexible manufacturing, and adaptive logistics — enabling high degrees of personalization and rapid responses.

Chen Hsong officially launches the iChen System 4.0 — intelligent, cloud-based networking and data management solution for the masses. On the show-ground, a dashboard displays the dynamic statuses of all connected injection moulding machines and auxiliary equipment, as well as real-time monitoring data such as power consumption. Data is stored seamlessly to the cloud, analytics provided by Big Data background services, and users can access the entire range of manufacturing information via mobile phones and other peripherals through well-known client technologies such as mobile apps, web apps, PC productivity software such as Excel, and WeChat interfaces.

The all-new Japanese-designed CPC/MPC-6.0 advanced computer controller and the CBmold® series of advanced controllers from Beckhoff® all support standardized Industrie 4.0 connectivity seamlessly, so your should never worry your machines going out-of-date.

Automation: More Than a Fad

Automation has always been an over-promised proposition, until recently when it is now propelled to the forefront of “new manufacturing.” Chen Hsong believes that the future leaders in industrial machinery will be those who dare to lead this charge towards providing customers with seamless automation and intelligent connectivity experiences. That is why we are showcasing these advanced solutions you see on display — and not just in exhibitions, we will help you “move” these solutions to your production lines as well!

Be There!

We look forward to hosting you at the China Import and Export Fair (Pazhou Complex) in Guangzhou from 16th May to 19th May. Remember our location and head straight to Hall 4.1, Booth D01. Our professional staff stands ready to answer all your questions and give you the high-quality experience you deserve!

Be There, or…