Three Years!

That’s how long it has been since the last K-Show back in 2013. And we haven’t been staying idle – we’ve put these three years to good use, developing new products and technologies you’ll be amazed at.

So, what are we up to for this this year’s K-Show?

You simply won’t be disappointed with our line-up for this big one. They are almost all brand new product lines, or at least significant upgrades to old product lines – such as a second-generation two-platen, a new all-electric, a new high-speed, a fast IML, as well as a revamped Euroseries.

Looks Can Be Deceptive

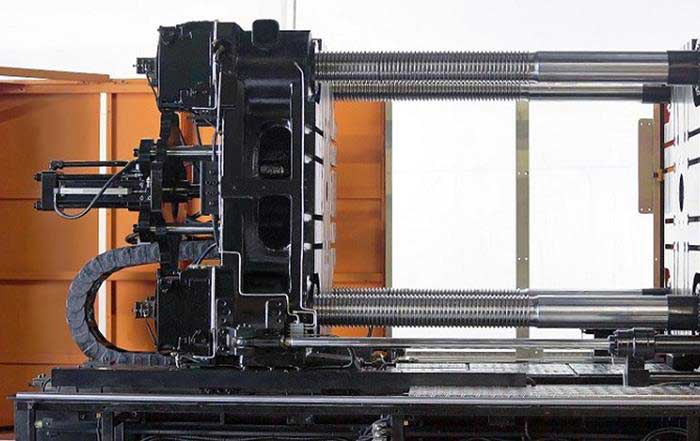

First of all, there’s our all-time favourite – the two-platen large-tonnage machine. On display is our second-generation, SUPERMASTER 700-TP with 700 tons of clamping force. To a careful eye, it looks very similar to the one we showed during the last K-Show, but that’s where the similarities end. Advanced third-generation servo-driven power-packs, new “precision” hydraulics, the CBmold800 controller from Beckhoff® and an EtherCAT™ digital bus – almost everything aspect of this machine has been improved upon and relentlessly fine-tuned by our in-house experts, many of them senior Japanese engineers from Mitsubishi Japan. As one of them puts it well, “it may look similar to the previous generation, it certainly won’t feel the same once you turn it on!”

SM700-TP Advanced Two-Platen

Deceptive looks indeed! The second-generation TP-series runs circles around the old, thanks to the new precision hydraulics, achieving consistent repeatability within +0.1% under field conditions. It enables unique and exciting new applications such as automotive glass rimming and fabric compressive moulding. During the show, this SM700-TP will produce a nice flower pot for you to take away. Be sure to line up for one!

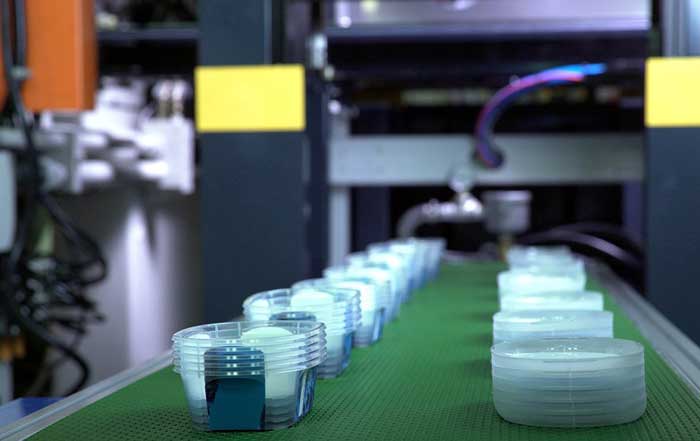

Another machine on display is also an old favourite, the SUPERMASTER 200TSV with servo-driven power-pack and a B&R SmartMold® controller, coupled with an IML system making food containers.

But observe closely (looks can be deceptive!) – we are not just shipping the same machine that you’ve seen before… Oh no. If you look close enough, it dawns on you – this machine is much faster! In fact, dry cycle of 2.8s and total cycle time (including robot take-out) of less than 5 seconds.

SM200TSV with IML

Our standard workhorse in the European market – the Euroseries – has also gone through a complete overhaul. On display is a second-generation upgrade, an EM80 Euroseries with full CE-safety compliance, Beckhoff® xMold controller, EtherCAT™ digital bus and servo-driven power-pack. This upgrade simply makes the Euroseries, already popular in European markets, better and more efficient in every way.

The new EM80 Euroseries

The Incredible New-ness of Being

By this time, you’re probably wondering where the new stuffs are. So, bewilder no more! We are launching a brand-new all-electric product line, dubbed the SUPERMASTER EJ-series! On display is an SM90EJ with 90-ton clamping force, each axis driven by independent Delta® servosystems with a Delta® advanced controller communicating through a lightning-speed, all-digital central bus. With 200mm/s (optional 350mm/s) injection speed as standard, all motions are so precisely controlled and tuned that the machine barely even shakes. And whisper-quiet too.

SM90EJ All-Electric

The SM90EJ will be producing high-end optical lens for the show.

What now… more, you say? You mean another new product line?

Yes! And I’m telling you that this turns out to be the one K-Show that we introduced the most number of new products! On display is another brand-new product line launched just recently – the MK6 (affectionately pronounced “Mark Six”) – series of small-to-medium-tonnage, high-speed, high-precision machines!

Since our strategic cooperation with Mitsubishi of Japan in 2011, Chen Hsong has really been rampaging up the technology curve. There have been so many new technologies rolling out, and so many new enhancements made, that we lost count of them all.

Emerging from this amazing wave of new-ness is the MK6-series, which was designed from the ground up to be a strong, all-rounded performer. Our goal was to produce a machine that matches typical Japanese high standards in terms of performance, quality, stability, repeatability and reliability. And with the MK6, in the opinion of the (retired) ex-chief-engineer of Mitsubishi who now works for Chen Hsong as a senior technical advisor, we have come really, really close.

SPEED168 with Take-out

And so, during the show, you’ll be able to see the MK6-series first-hand. On display is a high-speed version of it – the SPEED168 – with 168-ton of clamping force and 300mm/s injection speed, Beckhoff® xMold advanced controller, EtherCAT™ digital bus and all servo-driven power-pack. The machine will be making two-cavity disposable cups with cycle time of slightly over 3 seconds. Just look at the machine running and you’ll marvel, as we do ourselves, at its rock-solid stability, whisper-quiet, swift motions and repeatability that shows. That is why the MK6-series has been successfully used in such ultra-demanding applications such as four-color over-moulding!

Wrapping Up

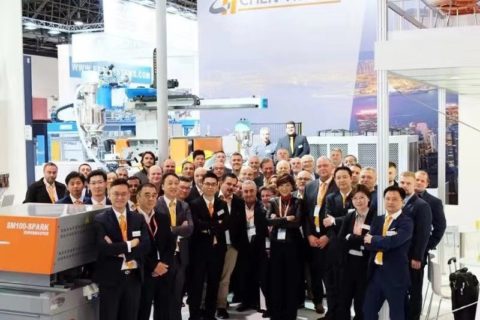

So, there, that’s all folks! Come and see them for yourself. Just in case you forget, the K starts on 19/10 in Messe Düsseldorf and runs until 26/10. Book your hotels early as they tend to get a tad full. We encourage you to also plan a visit to Chen Hsong Europe (http://www.chenhsongeurope.eu), in the Netherlands. Send email to info@chenhsongeurope.eu and our European colleagues will fix you up.

Chen Hsong is in Hall 13, Booth number B43… but I’m sure you’ll find us easily. Just look and follow the wows!

We’ll continue our live coverage of K 2016 on a regular basis – keep looking at this space!

See ya!