Power Tool Battery Casings with Dual Materials

Combining Two Materials to Injection Mold Power Tool Casings

A very demanding Injection Molding application is manufacturing parts that require use of two different materials. In this example, our customer in Chiayi City, Taiwan, China, has been manufacturing dual material power tool casings in PA and GF since 2017.

Employing 2 of our SM300DCV Toggle Dual-Material Type Injection Molding machines, our customer fills 4 cavities with a shot weight of 160g and achieves a cycle time of only 43s in fully automatic mode.

The SM300DCV Injection Molding machine delivers a clamping force of 300tons, driven by the Delta Servo-Drive and ARICO controller. This machinery combination features a multi-material system with integrated turn-table for maximum effectiveness.

Click and read more…

Machine Details

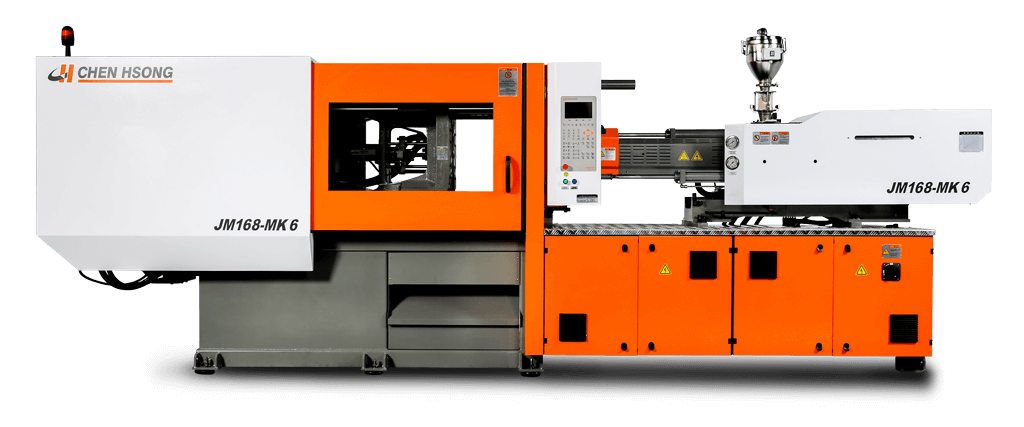

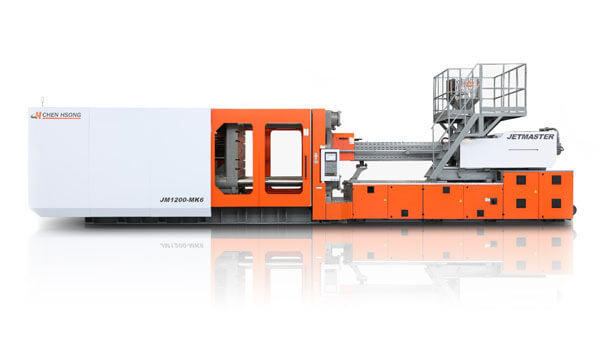

Model: JM168-MK6

Model: JM168-MK6

Type: High-Speed Toggle

Year: 2015

Clamping Force: 168 tons

Power Pack: SVP/3 Servo-Drive

Controller: Beckhoff CBmold300

Operator Details

Country: CHINA

Location: Guangdong Province

Number of Machines: 100+

Status: One of the largest power tools brands in the world

Part Details

Part: Power Tool Battery Casing

Resin: PC + ABS (Fire-Retardant)

Product weight: ???g

Cycle Time: 29 sec.

Yield: 99%

Op Mode: Fully-automatic

Features

-

Precision Hydraulics™

Precision Hydraulics™ -

Over-Moulding

Over-Moulding

Share this Case Study