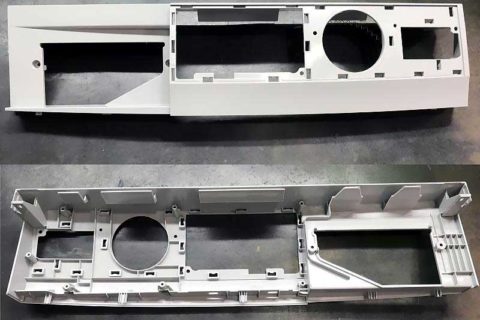

Refrigerator Parts

Injection Molding of Refrigerator Parts in Polypropylene

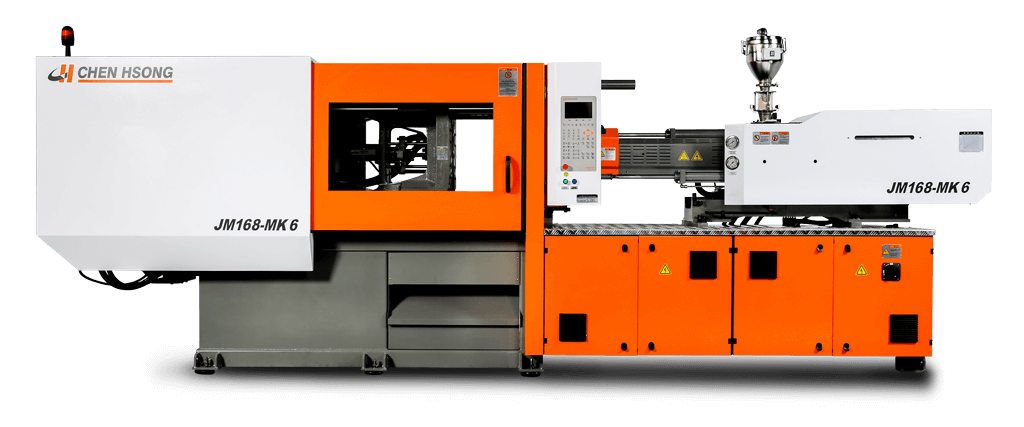

In China, a customer in Foshan, Guangdong Province, has been using 35 of our EM320-SVP/3 Toggle Type Injection Molding machines to manufacture refrigerator parts in polypropylene (PP) since 2015. Each injection molding machine applies a clamping force of 320 tons, driven by an SVP/3 Servo Drive and controlled by a Nippobatta Ai-02 unit.

The shot weight for each item is 230g, with a thickness of 2mm. In fully-automatic mode this configuration achieves a cycle time of only 36 seconds.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: EM320-SVP/3

Model: EM320-SVP/3

Type: Toggle

Year: 2015

Clamping Force: 320 tons

Power Pack: SVP/3 Servo-Drive

Controller: Nippobatta Ai-02

Operator Details

Country: CHINA

Location: Foshan, Guangdong Province

Number of Machines: 35

Part Details

Part: Refrigerator Part

Resin: PP

Dimensions: 63mm x 203mm x 100mm

Product weight: 230g

Thickness: 2mm

Cycle Time: 36 sec.

Op Mode: Fully-automatic

Share this Case Study