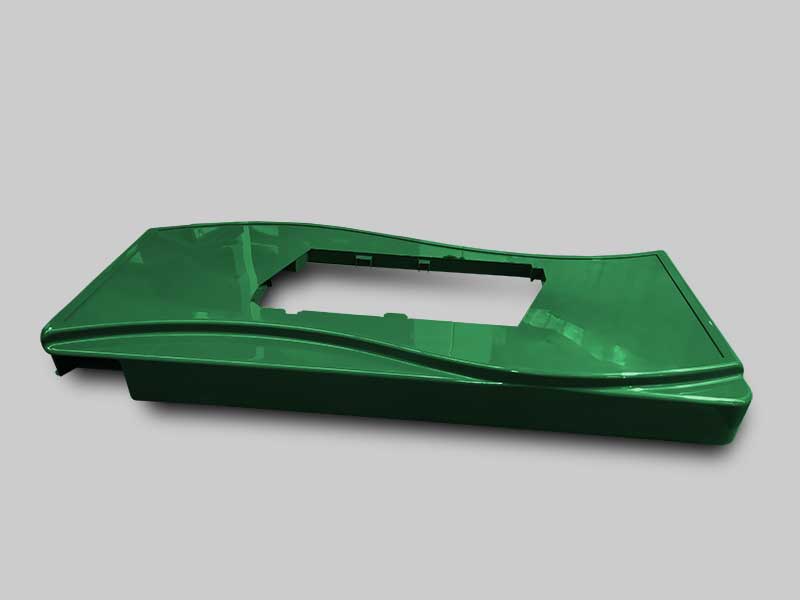

Vending Cabinet Top Cover

Injection Molding of Vending Cabinet Top Cover

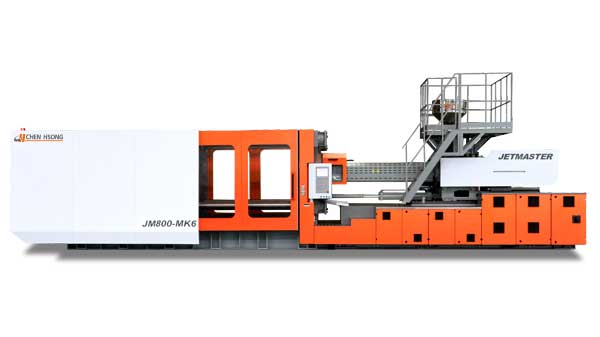

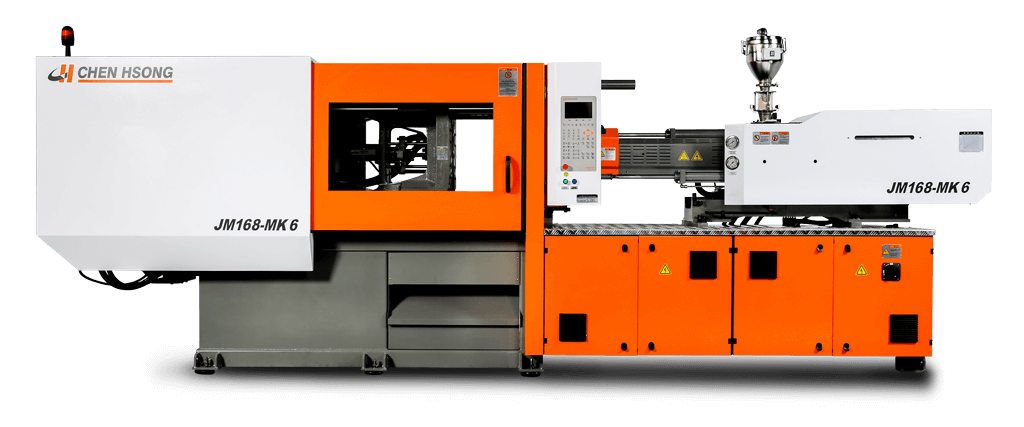

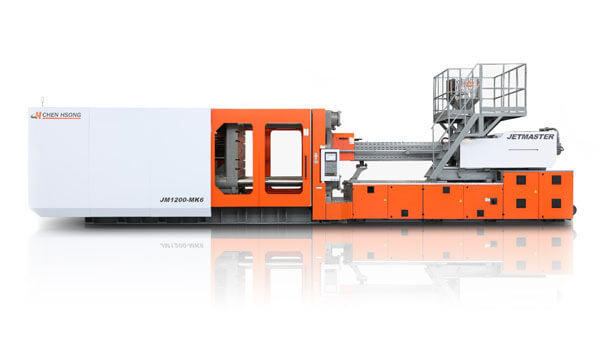

The above video shows one of our customers in the plastic injection molding industry using the high efficiency MK6 series to manufacture a vending cabinet top cover. The injection molding machine toggle 1000 tons of clamping force to form each top cover, running in automatic mode with the MPC7.0 controller, each cycle time is 52 sec, with product weight of 700g.

All aspects of the JETMASTER MK6 injection moulding machine (including the clamping mechanism, machine base, and injection unit) have been significantly enhanced and strengthened for higher precision. Chenhsong technicians have relentlessly optimized the control system and hydraulics to achieve superior efficiency and overall stability. All these have improved Chen Hsong’s machines’ performance, thus helping clients increase their productivity and products’ acceptance rate.

Machine Details

Model: JM1000-MK6

Model: JM1000-MK6

Type: Toggle Type

Clamping Force: 1000 tons

Controller: MPC7.0

Part Details

Part: Top Cover of Vending Cabinet

Resin: ABS

Cavities: 1

Product weight: 700 g

Cycle Time: 52 secs.

Op Mode: Fully automatic

Other

-

Pickup method: Robotic Arm

Pickup method: Robotic Arm

Share this Case Study