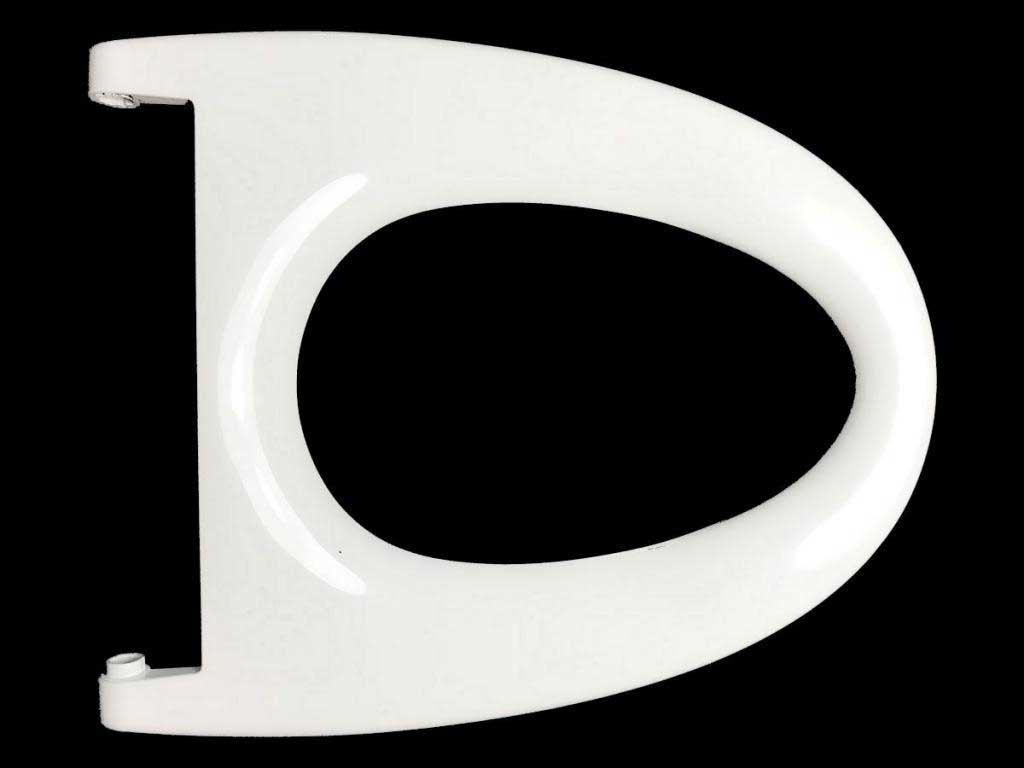

Toilet Seats

Toilet Seat Manufacture in Polycarbonate and ABS Using the EM480-SVP/3+ Injection Molding Machine

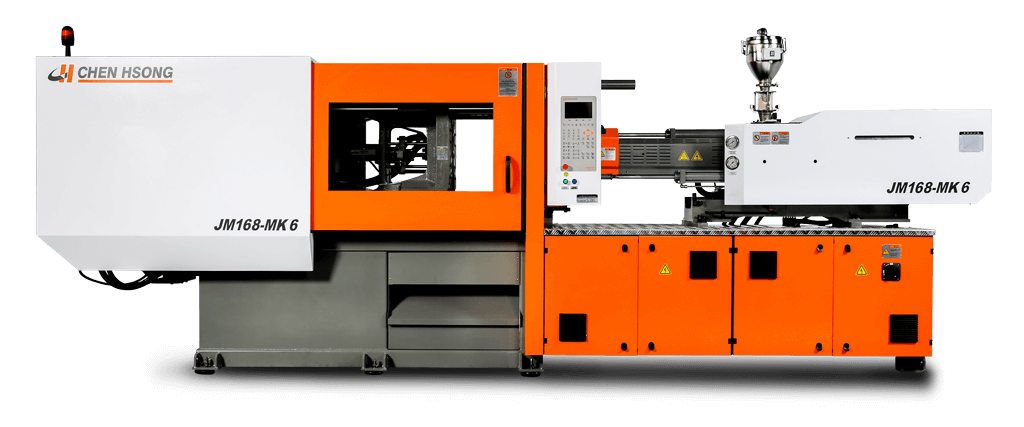

In Zhejiang Province, China, one of our customers is employing 5 of our EM480-SVP/3+ Injection Molding Machines to manufacture polycarbonate (PC) and ABS toilet seats with a shot weight of 527g and thickness of 6mm.

The EM480-SVP/3+ driven by the SVP/3 Servo-Drive and controlled by a Nippobatta CPC 6.0 achieves a clamping force of 480 tons and a cycle time of 55s in semi-automatic mode. This successful manufacturing enterprise has been operating our Machines since 2017.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: EM480-SVP/3

Model: EM480-SVP/3

Type: Toggle

Year: 2017

Clamping Force: 480 tons

Power Pack: SVP/3 Servo-Drive

Controller: Nippobatta CPC 6.0

Operator Details

Country: CHINA

Location: Zhejiang Province

Number of Machines: 5

Part Details

Part: Toilet Seat

Resin: PC + ABS

Dimensions: 467mm x 376mm x 28mm

Product weight: 527g

Thickness: 6mm

Cycle Time: 55 sec.

Op Mode: Semi-Automatic

Share this Case Study