Fakuma 2018

H.L.A. Corbey, General Manager of Chen Hsong Europe.

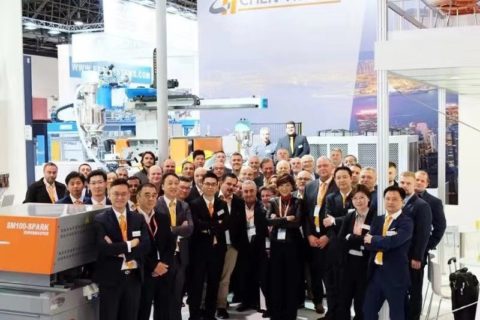

Chen Hsong Group celebrates its 60th year anniversary this year. At the fairgrounds of Fakuma 2018, Chen Hsong Europe strengthened its position in the European market with a showcase of two cutting-edge injection molding machines.

Chen Hsong Europe was established in May 2013, located in the Netherlands and is a wholly-owned subsidiary of Chen Hsong Group, one of the largest Chinese manufacturers of injection molding machines.

According to H.L.A. Corbey, General Manager of Chen Hsong Europe, Chen Hsong has already had presence in Europe with sound performance in Hungary, Poland, etc. The company has also built up connections and grown in the Netherlands, Italy, Spain, Portugal and France, and is putting great effort in Germany.

“For us, the German market is also growing, and we will focus more in this market. We are looking for new agents and more professional salespersons, aiming at unlocking more market potentials,” added H.L.A. Corbey.

“In the past, Asian machines were not generally accepted in Europe. However, the European market for Asian machinery is growing now,” he continued.

As he explained, the driving force for the growth is that European producers are looking for cost-efficient and high quality alternatives for European machines as the overall cost for production has been increasing.

Talking about the competitive advantages of Chen Hsong in the European market, H.L.A. Corbey said the company has a strong foundation of serving the industry for 60 years. The company has the technological know-how and is flexible in following customers’ needs. In addition, the delivery time for machines is shorter than European suppliers.

New SPEED Series and JETMASTER MK6 Series in the spotlight

The SPEED-PACK 260 was developed for fast and thin wall packaging.

At the booth of Chen Hsong, a SPEED-PACK 260 of the SPEED-PACK Series and a JM88-MK6 of the JETMASTER MK6 Series were showcased to the visitors. Both are new series of the company.

In particular, the SPEED-PACK Series was chosen for display at Fakuma because the company is targeting to explore the fast packaging market in Europe. With this new series, the company is very strong in fast packaging applications.

SPEED-PACK 260 was developed for fast and thin wall packaging. It has a maximum clamping force of 260t with maximum screw rotation speed of 300rpm.

Thanks to the speed controlled servomotors, the machines of JETMASTER MK6 Series are very energy efficient.

The machines of SPEED-PACK Series and JETMASTER MK6 Series are equipped with speed controlled servomotors. The system pressure is measured real-time by a pressure sensor. In this way, it can provide the required flow according the requirement to eliminate non-functioning consumption. In total, this leads to lower energy consumption, high precision, low noise and low inertia.

For technology trends of injection molding machines, H.L.A. Corbey emphasized that high speed and high energy saving are the most sought after requirements from customers. More turnkey solutions are also needed in some sectors.

He also highlighted that Chen Hsong machines are equipped with Industry 4.0 features that meet the latest EUROMAP 77 standard, collecting information and providing remote services.

“The next step for us will be introducing advanced preventive functions such as maintenance alerts,” concluded H.L.A. Corbey.

Reprinted with permission from CPRJ, October issue.