This year Chen Hsong (CH) had a very significant presence in CHINAPLAS 2018, which attracted 80,701 visitors. It was easy to locate the Chen Hsong booth that was packed with people, a shining star among the exhibitors, and a must visit destination for visitors.

The jam-packed Chen Hsong booth

Constant customer enquiries

Chen Hsong exhibited the machines:

- SM700-TP: An advanced two-platen machine for large products.

- SPEED-PACK 400: A customisable machine for high speed packaging.

- EM320-PET: A speedy PET machine.

Chen Hsong received overwhelming response from visitors. The company

continues to amaze with delivery of high-speed, high-precision and advanced performance machines!

Highlight of the show — the MK6

SPEED-PACK high-speed packaging model

In 2011, Chen Hsong had a strategic cooperation with Ube-Mitsubishi, the expert of technology enterprise in Japan. During the show, Mr. Mizuno, Technical Director, Ube-Mitsubishi proudly highlighted the production capacity and quality of the Chen Hsong Group. He indicated the high integration capabilities combined with the superior design ability of Mitsubishi and outstanding production capacity of Chen Hsong Group; a combination that will build a new mark for the injection moulding machine industry, worldwide.

Mr. Mizuno says, “Chen Hsong Group is one of our most important cooperation partners. Chen Hsong is the excellent partner who can reach high quality and high efficiency. Chen Hsong is our best partner in the globe!”

Mr. Mizuno of Ube-Mitsubishi speaking at the Chen Hsong press conference

Mr. Mizuno of Ube-Mitsubishi with Chen Hsong leaders

On the second day of the trade fair (25th April, 2018), Chen Hsong Group held its 60th Anniversary Dinner Banquet at the Shanghai Hilton Hotel, inviting customers, collaborators, friends and families. The event received a resounding response with over 500 people attending!

Talks were given by Chairman of the Board and CEO, Lai Yuan Chiang and by Vice Chairman of the Board and President of Group Manufacturing Chi Kin Chiang. The evening saw very special performances. To add, the President of Ube-Mitsubishi, Koji Kubota made a speech highlighting that Chen Hsong was their most important cooperation partner for the global markets.

Mr. Kubota speaking at Chen Hsong banquet

Toast to the Next 60 Years for Chen Hsong!

60th Anniversary Celebration Banquet

What’s more, Chen Hsong group highlighted it MK6 — Servo Driven injection moulding machines, which is one of their top-selling series for the domestic and overseas market. The machine uses high-end Japanese technology and is “fast, precise and stable.” Well-renowned the world over, the machine boasts of a 98% repeat purchase rate.

MK6 with repeat purchase rate over 98%

Mr. Corbey, GM of Chen Hsong Europe, with clients

All Around Excellence

Chen Hsong continues to focus on perfection in quality and advanced technologies in serving its markets. They not only offer fine products and service, but also pursue innovation-based applications to meet customer needs so as to create higher value. The exhibition saw Chen Hsong Group bring many technologies new to everyone in the injection moulding industry.

Demo of Industrie 4.0 connectivity

OTS (One Touch Service)

Chen Hsong’s “One Touch Service” is a key strategy in its “Internet+” technology to upgrade the quality of service and products. Operated by one touch, this service allows users to connect to the Chen Hsong online service system efficiently, and thus enjoying the experience of injection moulding machines’ online manual maintenance instructions, after-sale maintenance appointment, online spare parts purchase and other high-quality after-sale service through a mobile phone.

In order to develop the “China Manufacturing 2025” initiative, Chen Hsong promotes the intelligent upgrade of its injection moulding machines with an endeavour to provide the best solution by the applications of IoT (Internet of Things) and CIC (Chen Hsong Industrial Cloud).

OTS (One Touch Service)

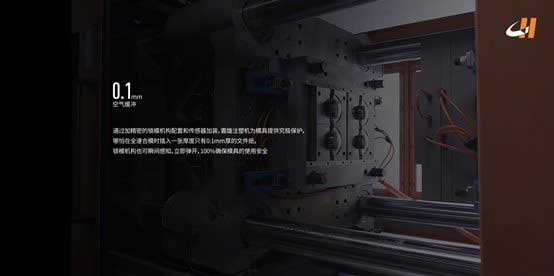

AIR Buffer™

Protecting moulds is one of the important processes during injection moulding. Chen Hsong Group has launched the patent technology “AIR Buffer”, which can provide unprecedented protection for the mould on the CH injection moulding machines. AIR Buffer, also known as “Algorithmic Interlocked Response”, is about installing a precision pressure sensor and servo system which deeply increases the design advantage of the clamping unit. It also offers the highest technology of AI control to link the whole system. AIR Buffer has extremely improved the machine responsibility.

To protect the mould surface while closing mould, this process needs to do the buffer protection in a very thin thickness during the mould movement. Even with a 0.1 mm thickness paper in the mould during the full speed mould closing, the clamping unit will instantly sense this and will open immediately. This ensures 100% mould safety. This special technology for mould protection, clearly proves that the CH group has the ability of pursue advance technology and meet customer needs.

AIR Buffer™

CIC (Chen Hsong Industrial Cloud)

“Chen Hsong Industrial Cloud” is the industrial big data storage for the intelligent injection moulding equipment. Through its IoT networks to collect all historical data during the use of the injection moulding machines, users can identify the nonlinear and non-logical relation between the controller and the product quality based on UGC data aggregation and algorithm enhancement, using artificial intelligence engines. As a result, optimised solutions for the performance adaptation and function adjustment of injection moulding machines with its set of the moulds can be offered.

CIC (Chen Hsong Industrial Cloud)

Having completed 60 years, the company is clearly working towards the next 60 years to create greater glories. The solidarity of Chen Hsong shows their absolute confidence and winning belief to the worldwide market and saying — Yes, We Can Do That! This is the moment, The Return of the King!