Air Conditioner Covers

High Gloss Injection Molding of Air Conditioner Covers

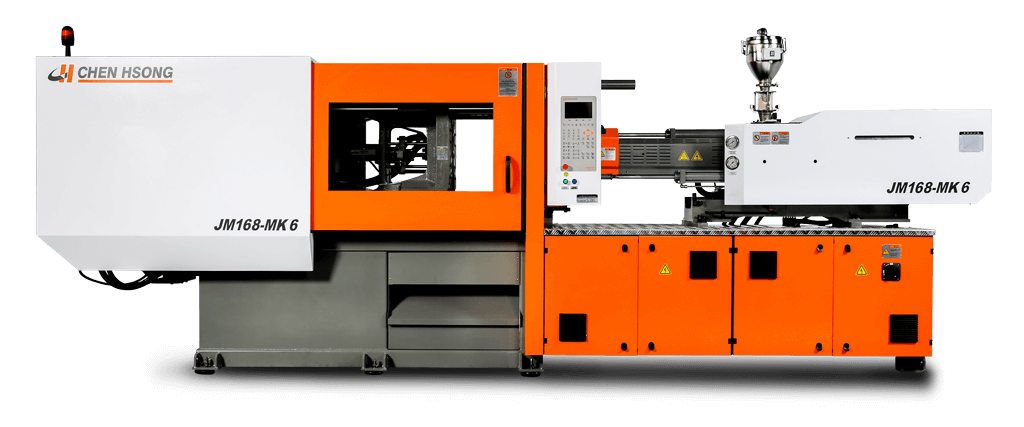

When a customer in Foshan, Guangdong Province, China, was looking for the ideal Injection Molding system for manufacture of high gloss HIPS resin air conditioner covers, the decision to utilise our JM488-SVP/3 Toggle Type Injection Molding machine with High Gloss capabilities was an easy one.

Powered by the SVP/3 Servo Drive and controlled by the Nippobatta Ai-12, all 30 machines being used to injection mold these parts since 2016 are achieving a cycle time of only 42s. With shot weight of 570g and thickness of 3mm in fully automatic mode.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: JM488-SVP/3

Model: JM488-SVP/3

Type: Toggle

Year: 2016

Clamping Force: 488 tons

Power Pack: SVP/3 Servo-Drive

Controller: Nippobatta Ai-12

Operator Details

Country: CHINA

Location: Foshan, Guangdong Province

Number of Machines: 30

Part Details

Part: Air Conditioner Cover

Resin: HIPS (High Gloss)

Dimensions: 790mm x 225mm x 170mm

Product weight: 570g

Thickness: 3mm

Cycle Time: 42 sec.

Op Mode: Fully-automatic

Features

-

High-Gloss Surface

High-Gloss Surface

Share this Case Study