Chair Backrest

Plastic Injection Molding of Chair Backrest

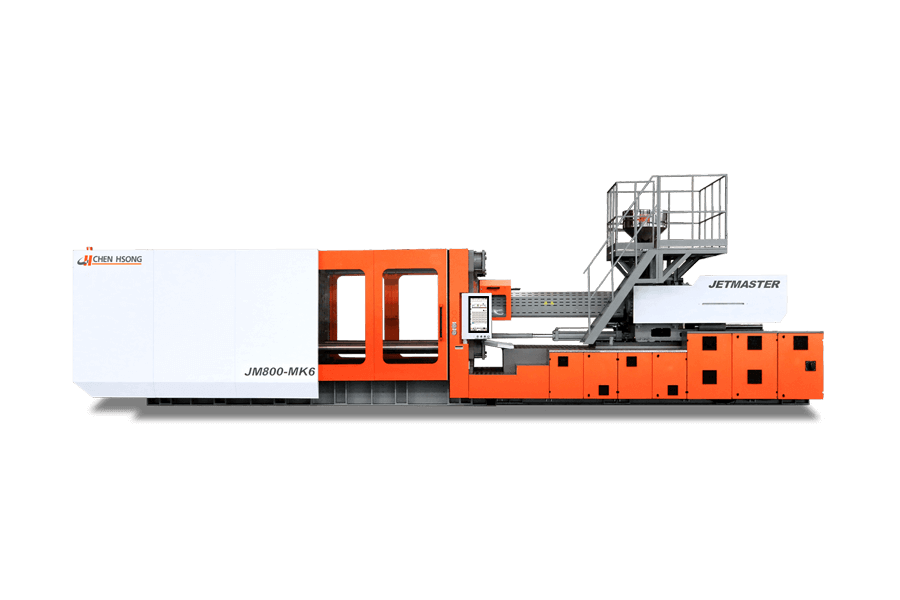

Elegant PC plastic and unique product finish come together thanks to the adaptable production capabilities of the JM800-C3-SVP/2 Injection Machine. 16 of these machines are being used for manufacturing of PC chair back rests and productivity is at an all-time high with an efficient turnkey solution being used in the Huaxin Economic Park in Hebei Province.

The challenge of a large volume product with its 2600g shot weight is met with the JM800-C3-SVP/2’s 800 ton clamping force. The Ai 12 controller and servo drive in semi-automatic operation mode smoothly controls the 1 cavity injection mold, putting out a 950x370x60 mm product with a wall thickness of 35mm in a cycle time of only 175 seconds.

The reliability of production obtained by the JM800-C3-SVP/2 injection machine series has opened doors for our client to reach international markets and expand their global distribution network.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: JM800-C3-SVP/2

Model: JM800-C3-SVP/2

Type: High-Speed Toggle

Year: 2016

Clamping Force: 800 tons

Power Pack: SVP/2+ Servo Drive

Controller: Ai 12

Operator Details

Country: China

Location: Hebei

Number of Machines: 16

Part Details

Part: Chair Backrest

Resin: PC

Cavities: 1

Dimensions: 950mm X 370mm X 60mm

Product weight: 2600 grams each

Thickness: 35mm

Cycle Time: 175 seconds

Op Mode: Semi-automatic

Share this Case Study