GPPS Clear Transparent Buffet Covers

Injection Molding GPPS Clear Transparent Buffet Covers

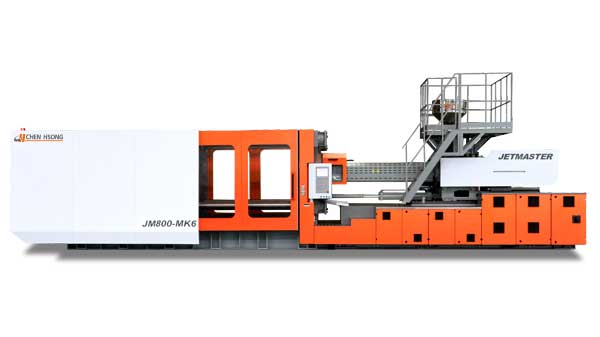

The above vidoe shows one of our clients in China that has been manufacturing food industry parts for well known international brands using our MK6 Injection Molding Machines, controlled by the MPC7.0 controller, delivering a clamping force of 800 tons.

The food and beverage industry is heavily regulated to ensure containers, industrial process components, and other parts comply with safety standards. As such, manufacturers use food-grade plastic materials for part design and construction, including plastic injection molding. Plastic injection processes can create complex, identical goods with a low risk of error. This makes plastic an increasingly popular alternative to metal, with specific advantages regarding food and beverage safety.

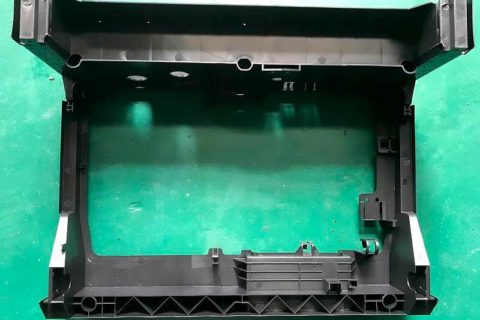

These high impact GPPS buffet covers are produced in 1 cavities with a shot weight of 830 g each and a cycle time of 53s.

Machine Details

Model: JM800-MK6

Model: JM800-MK6

Type: Toggle Type

Clamping Force: 800 tons

Controller: MPC7.0

Part Details

Part: Buffet Cover

Resin: GPPS

Cavities: 1

Product weight: 830 g

Cycle Time: 53 secs.

Op Mode: Fully automatic

Other

-

Pickup method: Robotic arm

Pickup method: Robotic arm

Share this Case Study