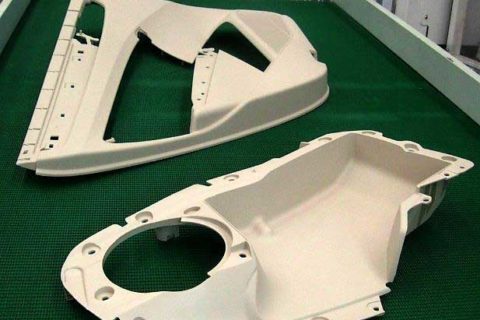

Valve Bodies

Valve Body Injection Molding In ABS And Glass Fiber

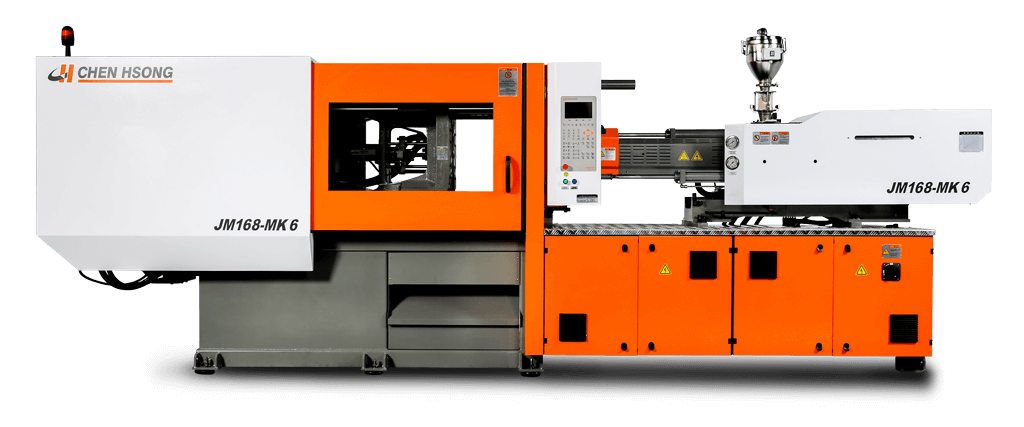

High performance products such as glass fiber (GF) ABS composite valve bodies require high performance machines, and this is why a customer in Zhejiang Province, China, chose to install 90 of our JM268-SVP/3 Toggle Type Injection Molding machines in 2015, to reliably produce very high volumes of these parts to exacting standards.

Applying a clamping force of 268 tons, powered by the SVP/3 Servo Drive and utilising a Nippobatta Ai-12 controller, the JM268-SVP/3 Injection Molding machine delivers a cycle time of 165 seconds with a shot weight of 364.1g and thickness of 7mm in semi-automatic mode.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: JM268-SVP/3

Model: JM268-SVP/3

Type: Toggle

Year: 2015

Clamping Force: 268 tons

Power Pack: SVP/3 Servo-Drive

Controller: Nippobatta Ai-12

Operator Details

Country: CHINA

Location: Zhejiang Province

Number of Machines: 90

Part Details

Part: Valve Body

Resin: ABS + 10% GF

Dimensions: 124mm diameter x 128mm

Product weight: 364.1g

Thickness: 7mm

Cycle Time: 165 sec.

Op Mode: Semi-automatic

Share this Case Study