Power to evolve comes from the philosophy to satisfy customers’ needs

Yea Wen Plastic, a well-known electronic products OEM manufacturer was established in 1972, who insist on being a professional OEM, where over a hundred well-known international companies have received its services, including HITACHI, JVC, Garmin and many more. Yea Wen Plastic upholds the philosophy in doing business: regarding customer’s needs with utmost importance. Their business includes the production of simple plastic products to mould development and the processing components. The integration of both upstream and downstream development ensures best product quality and provides a complete one-stop service for their customers.

Yea Wen Plastic and Chen Hsong join hands in the 3C light-weight and realistic-texture era

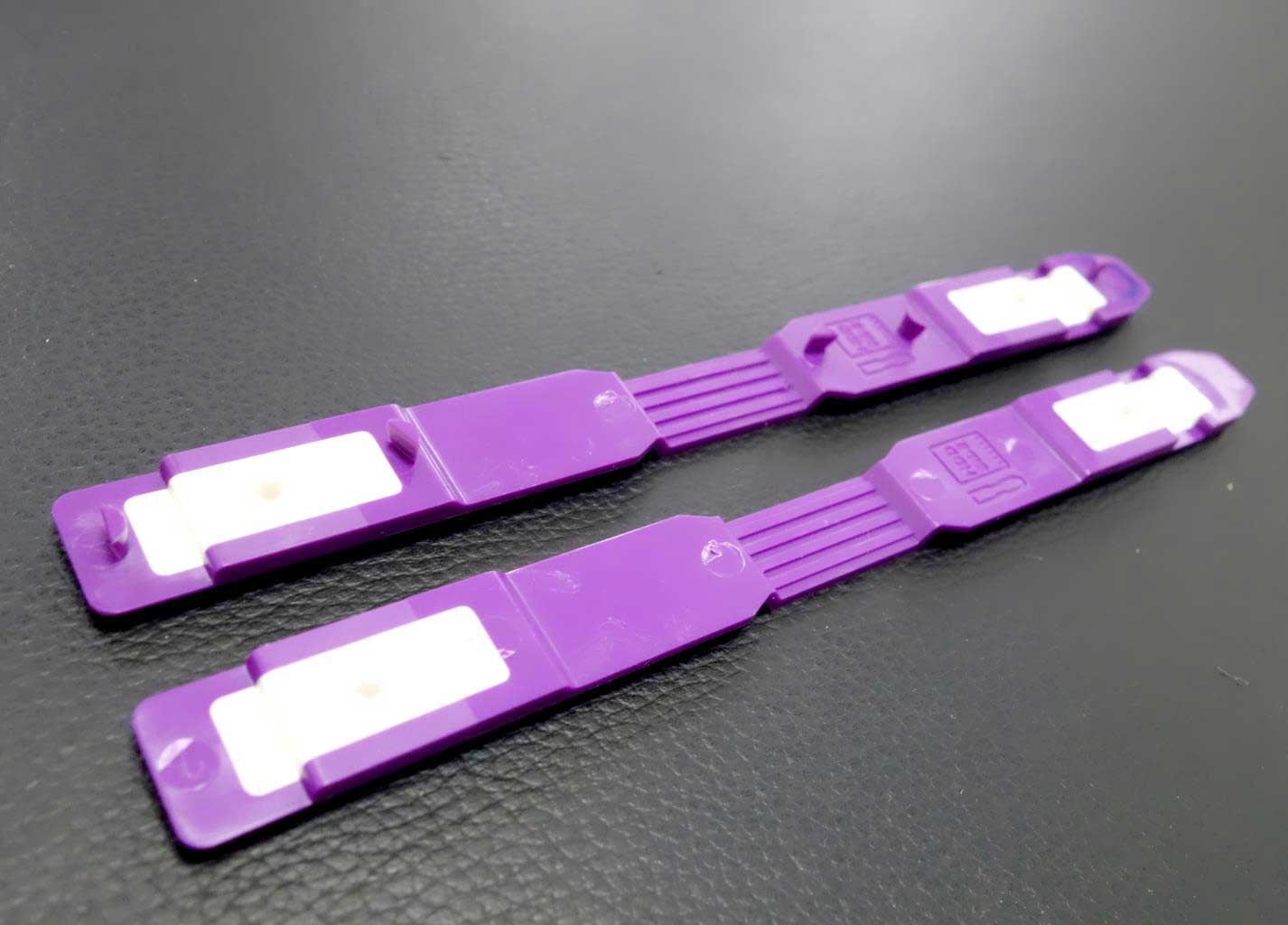

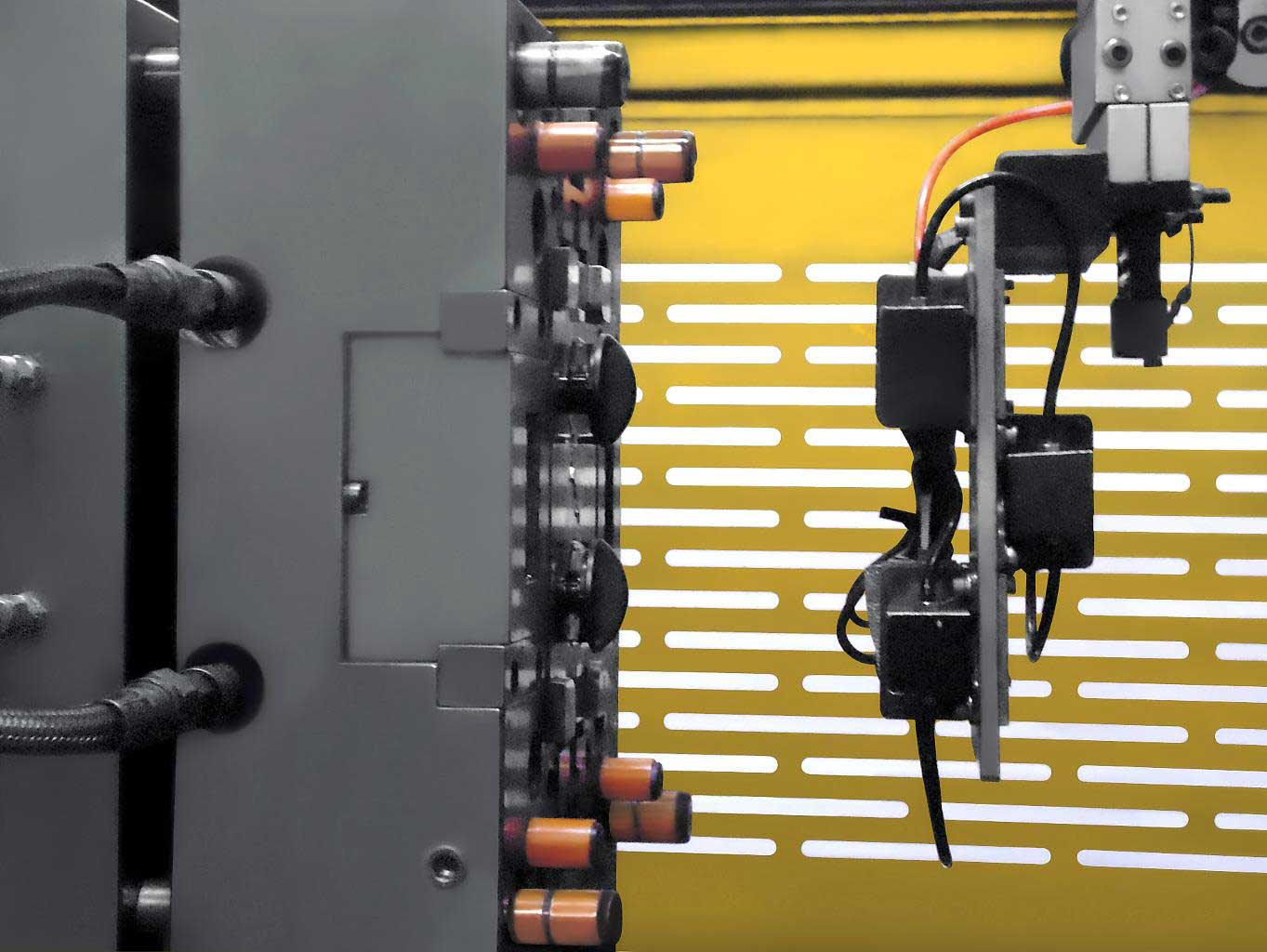

Yea Wen Plastic has been using Chen Hsong’s injection moulding machines for 26 years. Together with Chen Hsong, they successfully got into the high-end realistic texture market of 3C products. Chen Hsong’s injection moulding machines not only have outstanding performances in the 3C glossy products, but also got recognition from the improvement in the precision of the product formation, and contraction of the highly-sophisticated nitrogen-assisted moulding. These excellent performances enable Yea Wen to build solid customer relationships, and also bringing more potential orders. Chen Hsong Machinery and Yea Wen Plastic have long established a favourable long-term relationship. Each time when Chen Hsong introduces new products, whether it is the two-colour injection moulding machine or a new generation of electric injection moulding machine, Yea Wen would support without hesitation; they are always among the pioneer using Chen Hsong’s latest creations.

A trustful relationship rooted from Chen Hsong’s high-quality products and sincere services

Yea Wen Plastic has its own professional knowledge on the selection and mastery of injection moulding machine. They particularly emphasise on choosing Chen Hsong’s injection moulding machine due to its accuracy, stability, and good performances under high pressure low speed situation, they can quickly and accurately change moulds and machines. At the same time, by using Chen Hsong’s servo energy-saving injection moulding machine, they have increased our market competitiveness and profitability.

In addition, besides bringing high returns to Yea Wen through Chen Hsong’s injection moulding machine, customers are really touched by Chen Hsong’s speedy customer services. Chen Hsong’s maintenance staff is always able to precisely identify and solving any problem in time. Chen Hsong’s eagerness and sincere attitude made Yea Wen become more confident with Chen Hsong’s injection moulding machine, thus they continued to increase our orders as year goes by.

Advantages comes from the flexibility of Chen Hsong’s two-colour injection moulding machine

Yea Wen is located in the crowded Xin Zhuang District of New Taipei City. It occupied a small space, which requires making best use of the factory buildings. The same principle applies on the use of injection moulding machine. As early as Chen Hsong began to launch its two-colour injection moulding machine, Yea Wen knew well that “opportunity favours the prepared mind.” They have an insight into the market trends: it would be more favourable to spend on a two-colour moulding than stick to the second processing. They therefore determined to buy Chen Hsong’s 180 tons two-colour injection moulding machine. Initially, Yea Wen did not have two-colour orders and technology, so they use of the two-colour injection moulding machine to produce mono-colour products. At the same time, with the help from Chen Hsong’s two-colour moulding professionals on technical guidance and training; Yea Wen continue to work hard until we finally master the two-colour forming technology. Therefore, when customer has a two-colour product order, Chen Hsong’s two-colour injection moulding machine will undoubtedly increase the competitive advantage of Yea Wen. They then became one of the earliest OEM service providers to have the two-colour injection moulding machine. Hence, they are able to provide customers with wider and better choices.

Yea Wen Plastic actively prepares for a better future, and in 2016, they got both the ISO16949 and ISO13485 certifications. They constantly strive to enter the automotive and medical products market. In order to have better development, Yea Wen hopes to work with Chen Hsong in order to join hands in entering the 4.0 era of smart control industry, so as to create a better prospect together.