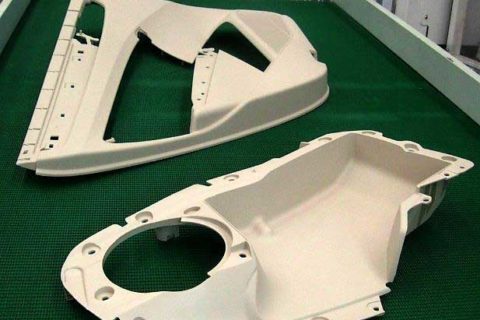

Rear Door Map Pockets

Fully Automatic Plastic Injection Molding of Car Rear Door Map Pockets

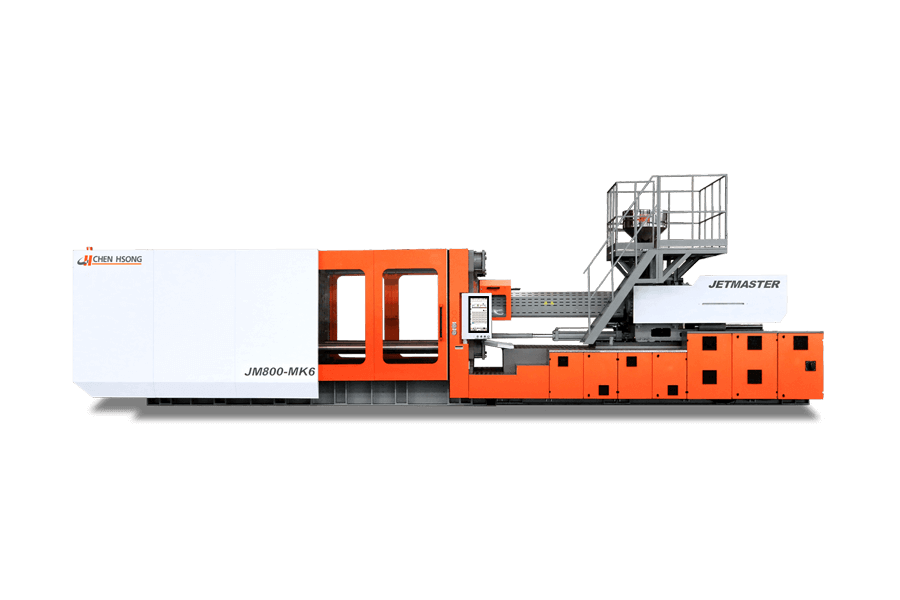

30 of our JM650-C3-SVP/2 Injection Molding Machines are working full-time in Shunyi District, Beijing to manufacture car rear door map pockets.

Operating in fully automatic mode, two rear door map pockets are completed in a cycle time of 35 seconds as a robotic arm offloads the parts, delivering high quality parts in time to meet the manufacturers strict deadlines.

The JM650-C3-SVP/2 is a High precision servo driven plastic injection molding machine, with up to 650 tons of clamping force. In this particular configuration the machine is filling 2 cavities with a shot weight of 211 grams each. The part is made of PP with a wall thickness requirement of 2mm.

Operating consistently since 2015, these 30 plus JM650-C3-SVP/2 Injection Molding Machines fitted with custom Nippobata Ai-12 controllers undergo regular maintenance by our Service team and are an invaluable asset in our customer’s manufacturing capabilities.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: JM650-C3-SVP/2

Model: JM650-C3-SVP/2

Type: High-Speed Toggle

Year: 2016

Clamping Force: 650

Power Pack: SVP/2+ Servo Drive

Controller: Ai 12

Operator Details

Country: China

Location: Beijing

Number of Machines: 30

Part Details

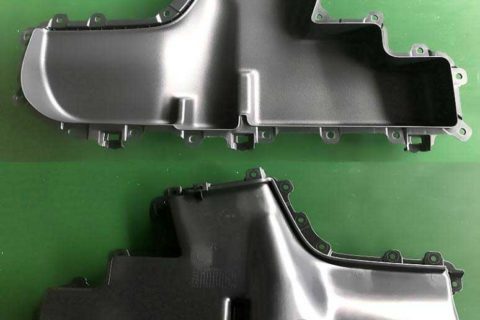

Part: Rear Door Map Pockets

Resin: PP

Cavities: 2

Dimensions: 415mm X 203mm X 89mm

Product weight: 211 grams each

Thickness: 2mm

Cycle Time: 35 seconds

Op Mode: Fully-automatic

Share this Case Study