Seat Cushion

Plastic Injection Molding of Car Seat Cushions

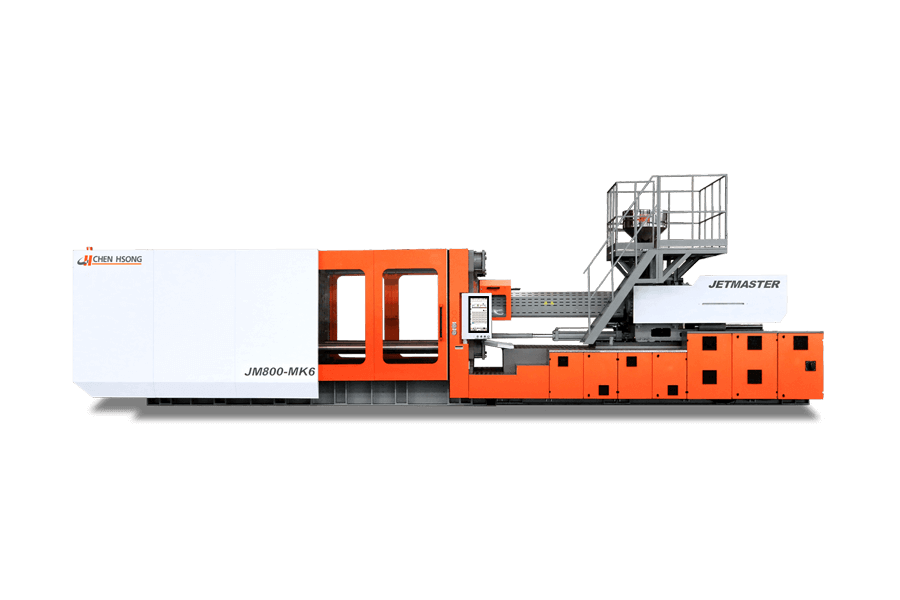

Durability and function require dependability in all phases of plastic injection parts manufacturing. Plastic injection molding of seat cushions is no exception. A sturdy construction, with an ergonomic knurled surface is a requisite for our client. The JM650-C3-SVP/2 plastic injection machine is fully capable of meeting these requirements.

16 machines are presently producing Seat cushions in the Huaxin Economic Park in Hebei Province. Each machine has a clamping force of 650 tons, with an Ai 12 Controller installed. Operating in semi-automatic mode, using PP plastic, with a shot weight of 620 g., each machine produces the 400x397x30 mm seat with wall thickness of 5mm in a cycle time of 104 seconds.

The superb technological innovations of the JM650-C3-SVP/2 plastic injection machine, will enhance your production performance, and technical support is, as always, a part of our product assurance.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: JM650-C3-SVP/2

Model: JM650-C3-SVP/2

Type: Toggle

Year: 2016

Clamping Force: 650 tons

Power Pack: SVP/2+ Servo Drive

Controller: Ai-12

Operator Details

Country: China

Location: Hebei

Number of Machines: 16

Part Details

Part: Seat Cushion

Resin: PP

Cavities: 1

Dimensions: 400mm X 397mm X 30mm

Product weight: 650 grams each

Thickness: 5mm

Cycle Time: 104 seconds

Op Mode: Semi-automatic

Share this Case Study