Volkswagen Protective Guard

Volkswagen Protective Panel Manufacture with the Two-Platen SM1650-TP Injection Molding Machine

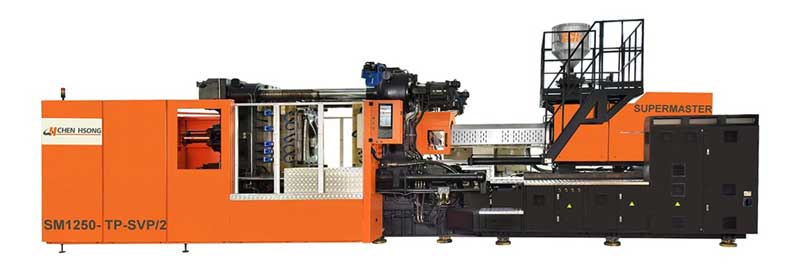

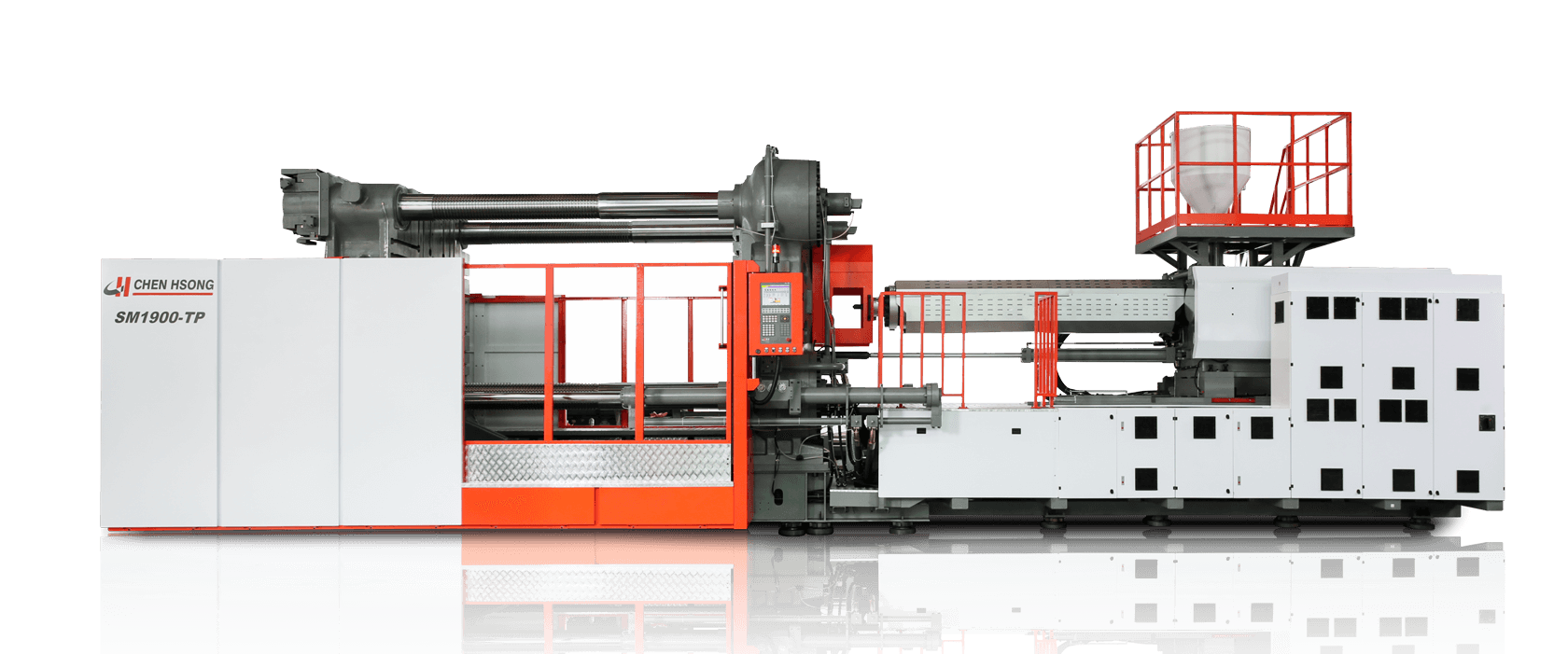

A customer in Jilin Province has more than thirty of our Two-Platen SM1650-TP Injection Molding Machines operating continuously in fully automatic mode, manufacturing parts as a Tier-1 supplier for the prestige Volkswagen brand. Our SM1650-TP is powered by the SVP/2 Servo-Drive, controlled by the Nippobatta AI-12 system. A clamping force of 1,650 tons is applied to a two cavity system with a shot weight of 1,250g. Cycle time is only 65s, and the parts are manufactured from PP/PE-TD20 resin.

Operating since 2015, this application of the SM1650-TP Injection Molding Machine demonstrates reliability and efficiency in manufacturing products to the highest international specifications.

Machine Details

Model: SM1650-TP

Model: SM1650-TP

Type: Two-Platen

Year: 2015

Clamping Force: 1,650 tons

Power Pack: SVP/2 Servo-Drive

Controller: Nippobatta Ai-12

Operator Details

Country: CHINA

Location: Jilin Province

Number of Machines: 30+

Status: Tier-1 auto-parts supplier

Part Details

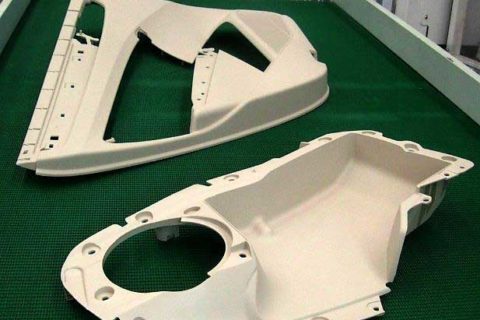

Part: Volkswagen Guard

Resin: PP/PE-TD20

Cavities: 2

Product weight: 1,250g

Cycle Time: 65 sec.

Op Mode: Fully-automatic

Share this Case Study