Microwave Oven Accessories

Injection Molding of Microwave Components in SPS Resin

In Foshan Province, a well known appliance manufacturer is producing Microwave accessories in SPS resin. SPS resin shot into an 8 cavity mold is then transformed into heat resistant microwave components in a cycle time of 37.3s.

SPS is a heat-resistant engineering plastic proprietary, polystyrene-based specialty resin that has wide applications in industrial and home products – particularly electronics –

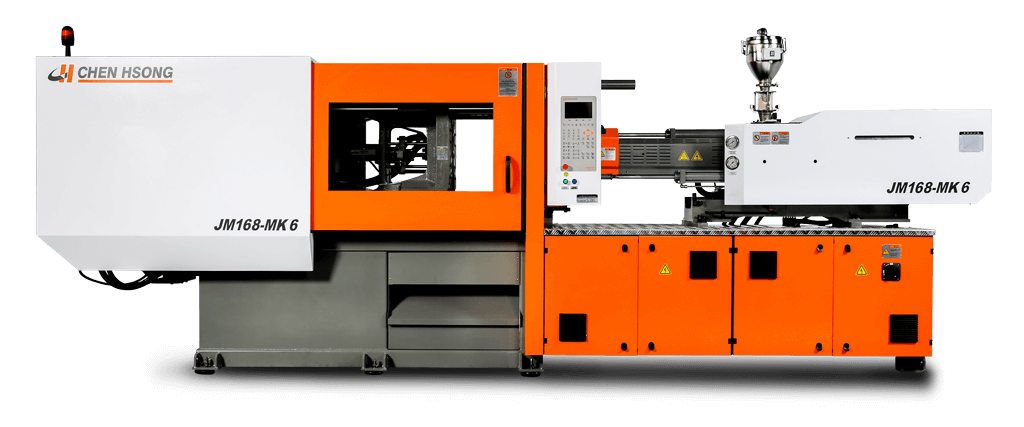

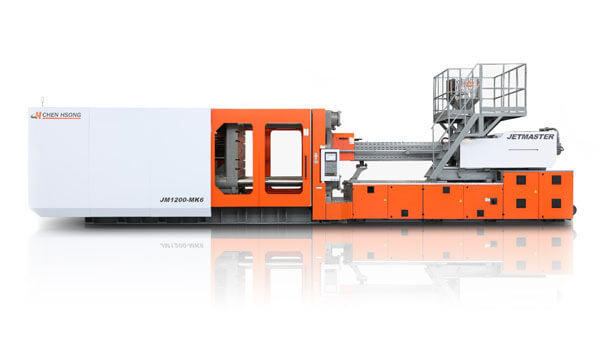

Reliable production is acheived using our JM208-MK6 Toggle Type Plastic Injection Molding Machines with our MK6 servo drive technology and controlled with the CPC6.0 controllers. The customer is very satisfied that our Injection Molding solutions have easily proved equal to the task of meeting the exacting requirements of high end manufacturing.

Machine Details

Model: JM208-MK6

Model: JM208-MK6

Type: Toggle

Clamping Force: 208 tons

Controller: CPC6.0

Operator Details

Country: China

Location: Foshan

Part Details

Part: Microwave Oven Accessories

Resin: SPS

Cavities: 1 out of 8

Cycle Time: 27.3 seconds

Op Mode: Fully automatic

Features

- Pickup method: Automatically fall off

Share this Case Study