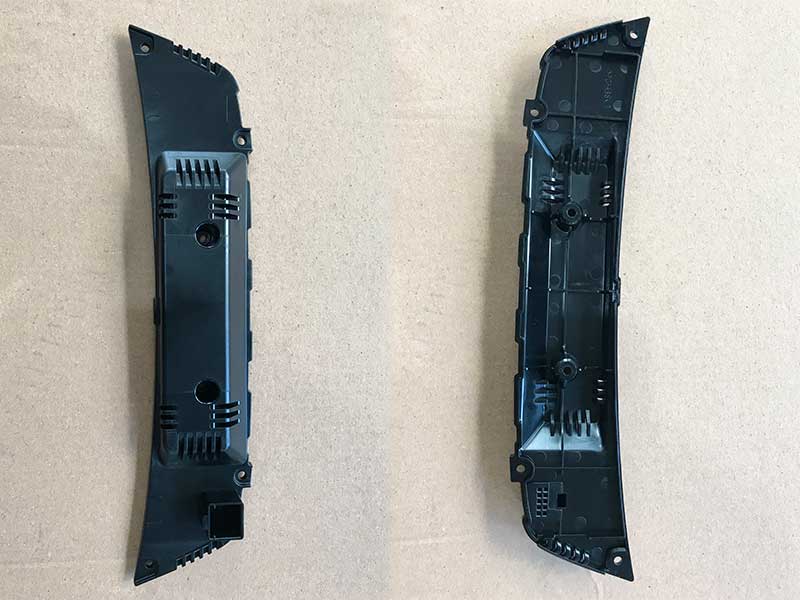

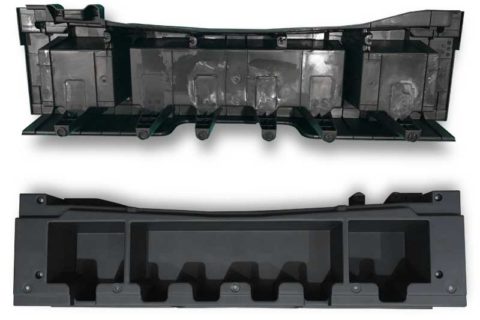

Car Component Base Panels

Injection Molding Car Component Base Panels

Located in the Wenzhou Economic and Technological Development Zone,

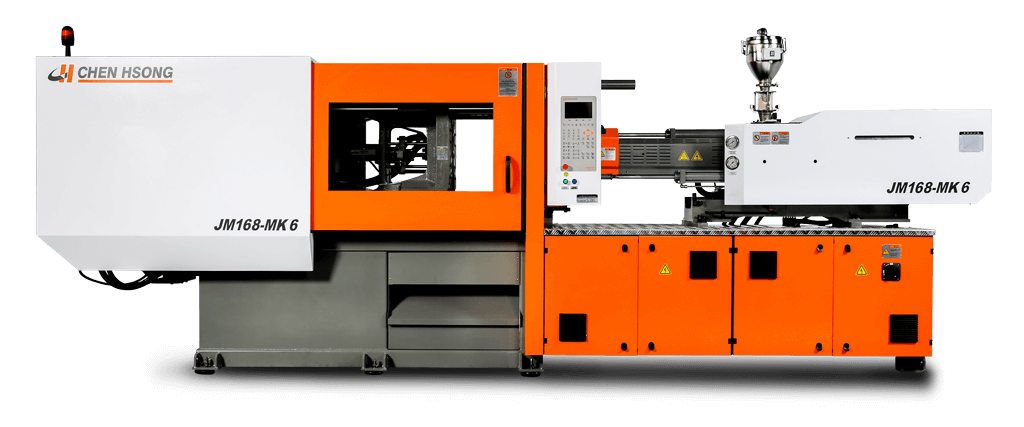

one plastic injection parts manufacturer with a well-known reputation in the automotive industry has been using Chenhsong Plastic Injection Molding Machines for many years. With over 50 EM150-SVP/2 machines in operation, our series of reliable and high performance machines have been a firm pillar in this client’s production line.

Using a mixture of PC + ABS Plastic, the EM150-SVP/2 injection machines are producing car component base panels. Using an Ai 02 controller in semi-automatic operation mode the EM150-SVP/2, with its 150 tons of clamping force gives smooth consistent production flow. For this product the double cavity mold is using a shot weight of 42.3 grams and is operating at a 28 second cycle time. Each 1 mm thick panel is 247x45x21 mm in size.

The EM150-SVP/2 model plastic injection machine is a reliable machine for large volume, rapid production of components with intricate details.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: EM150-SVP/2

Model: EM150-SVP/2

Type: High-Speed Toggle

Year: 2013

Clamping Force: 150 tons

Power Pack: SVP/2+ Servo Drive

Controller: Ai-02

Operator Details

Country: China

Location: Wenzhou

Number of Machines: 50

Part Details

Part: Car Component Base Panels

Resin: PC+ABS

Cavities: 2

Dimensions: 247mm X 45mm X 21mm

Product weight: 42.3 grams each

Thickness: 1mm

Cycle Time: 28 seconds

Op Mode: Semi-automatic

Share this Case Study