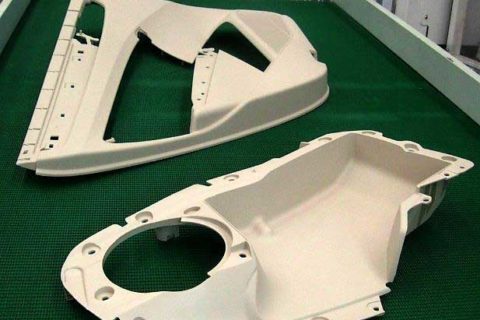

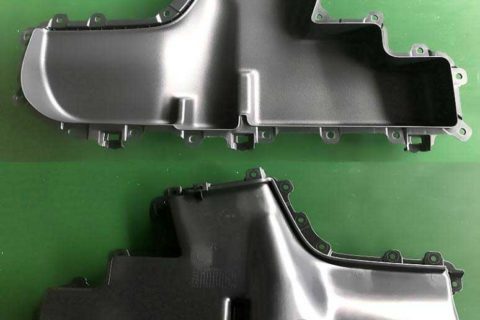

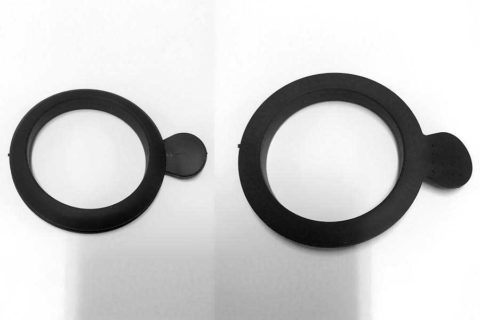

Lens for Automotive LED Lamps

Precision Injection Molding of Automotive LED Lamp Lenses

An example of the versatility of our Injection Molding Machinery can be seen in the application of our SM150HCV Direct-Clamping Injection Molding Machine, with a clamping force of 150 tons driven by the Delta Servo-Drive using the B&R SmartMold88 controller and a Powerlink digital main bus.

Using 2 cavities and PMMA resin, the SM150HCV operates on a fully-automatic cycle time of 9 minutes with a shot weight of 50g to deliver a perfect LED lens product every time.

Machine Details

Model: SM150HCV

Model: SM150HCV

Type: Direct-Clamping

Year: 2016

Clamping Force: 150 tons

Power Pack: Delta Servo-Drive

Controller: B&R SmartMold88

Main Bus: PowerLink digital

Part Details

Part: Lens for LED Lamps

Resin: PMMA

Cavities: 2

Product weight: 50g

Cycle Time: 9 min.

Op Mode: Fully-automatic

Share this Case Study