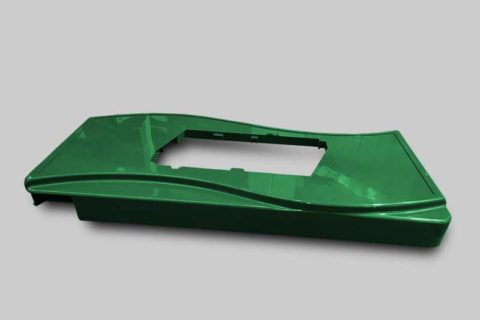

Light Box Back Covers

Injection molding of household components, light box end cover for the automotive industry

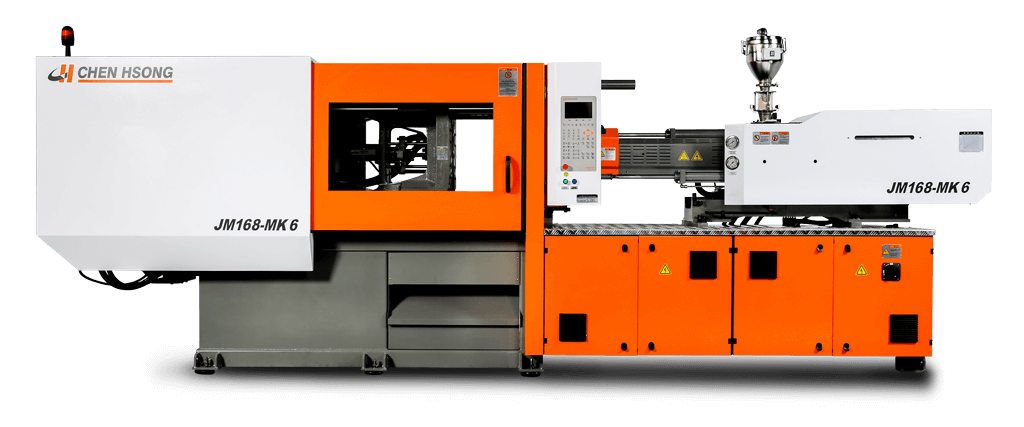

Speed, efficiency, and quality; all these are attained with the MK6e plastic injection molding machine.

With speed controlled servomotor, drives a fixed internal gear pump. The system pressure is measured real-time by a pressure sensor. In this way it can provide the required flow according the requirement to eliminate non-functioning consumption. In total this leads to lower energy consumption, high precision, low noise and low inertia.

Operating at a clamping force of 155 tons and using the latest CP6.0 controller the MK6e is running smoothly in fully automatic mode this makes high volume production of ABS light box back enclosures an easy task for our client in the household industry.

This machine series has been replaced and upgraded by our newer series of injection moulding machines.

Click here for more details.

Machine Details

Model: JM260-MK6e

Model: JM260-MK6e

Type: Toggle

Clamping Force: 155 tons

Power Pack: spv/2

Controller: CPC 6.0

Operator Details

Country: CHINA

Location: Zhongshan City

Part Details

Part: Light Box End Cover

Resin: ABS

Cavities: 2

Cycle Time: 40 sec.

Op Mode: Fully-automatic

Features

-

Manipulator

Manipulator

Share this Case Study