Sink Covers

Injection Molding of PP Sink Covers

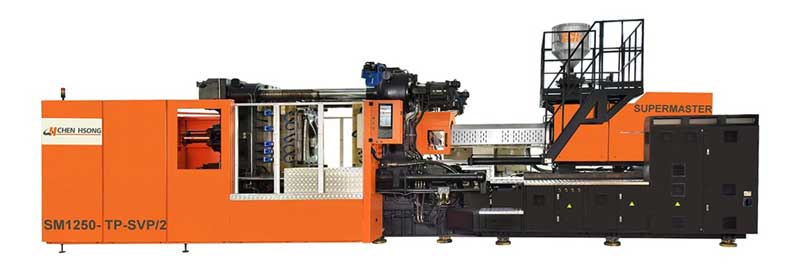

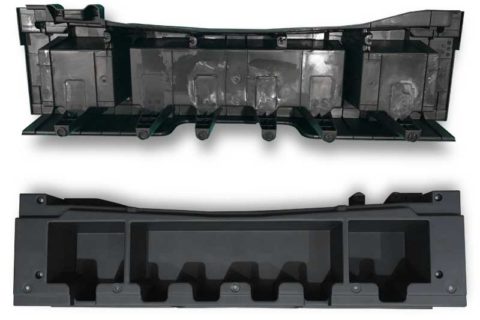

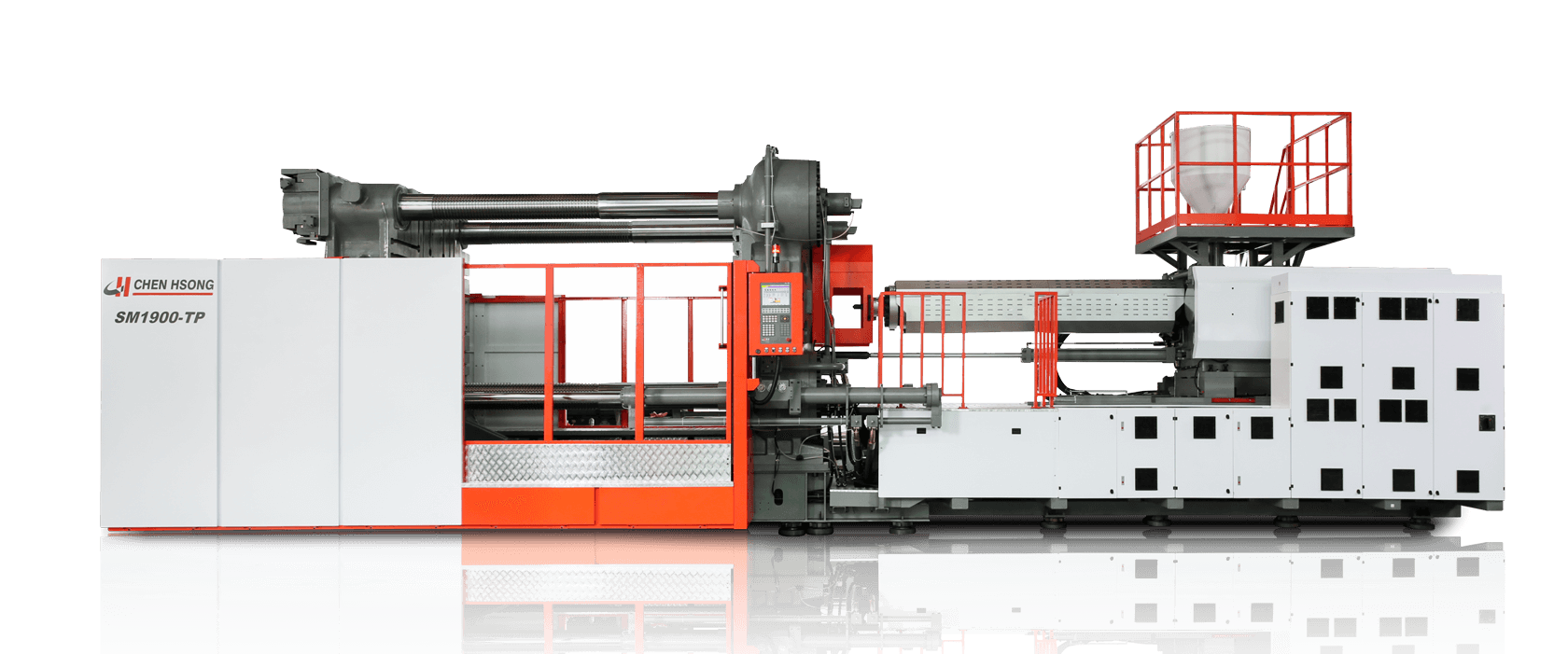

One of our clients in the Changchun Green Park has been using Supermaster 1050 TP-SVP/2 plastic injection mold machines in their production line since 2015. Using the mold’s duel 1 + 1 cavities, they are simultaneously producing left and right sink covers in a single cycle. The covers are 820x380x65 mm, and 800x350x65 mm with a wall thickness of 2 mm.

This manufacturer presently has 23 machines in operation. Each machine uses an Ai 12 controller, operates in semi-automatic mode and is set to a clamping capacity of 1050 tons. The covers being produced on these machines are made with 318 + 270 gram shots of PP, with a 63 second cycle time.

The flexibility of this two-platen machine makes it the perfect machine for production of larger components with high quality requirements and a high yield rate.

Machine Details

Model: SM1050-TP-SVP/2

Model: SM1050-TP-SVP/2

Type: Two-Platen

Year: 2015

Clamping Force: 1050 tons

Power Pack: SVP/2+ Servo Drive

Controller: Ai 12

Operator Details

Country: China

Location: Changchun

Number of Machines: 23

Part Details

Part: Sink Covers

Resin: PP

Cavities: 2

Dimensions: 820mm X 320mm X 65mm & 800mm X 320mm X 65mm

Product weight: 318 grams + 270 grams

Thickness: 2mm

Cycle Time: 63 seconds

Op Mode: Semi-automatic

Share this Case Study