Thin-Walled Siemens MRI Part

Precision Injection Molding for Global Leading Medical Equipment Manufacturer Siemens

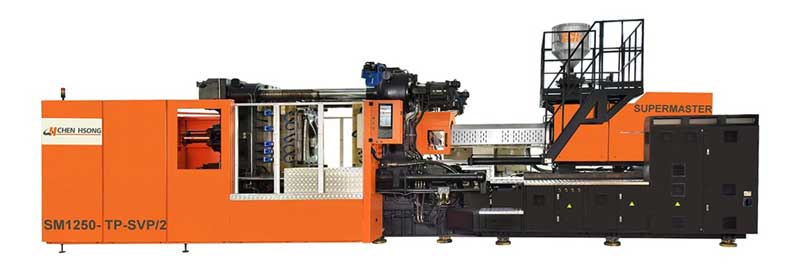

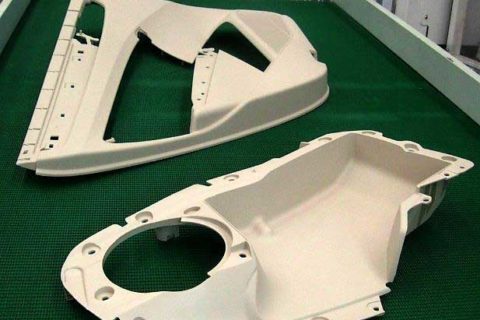

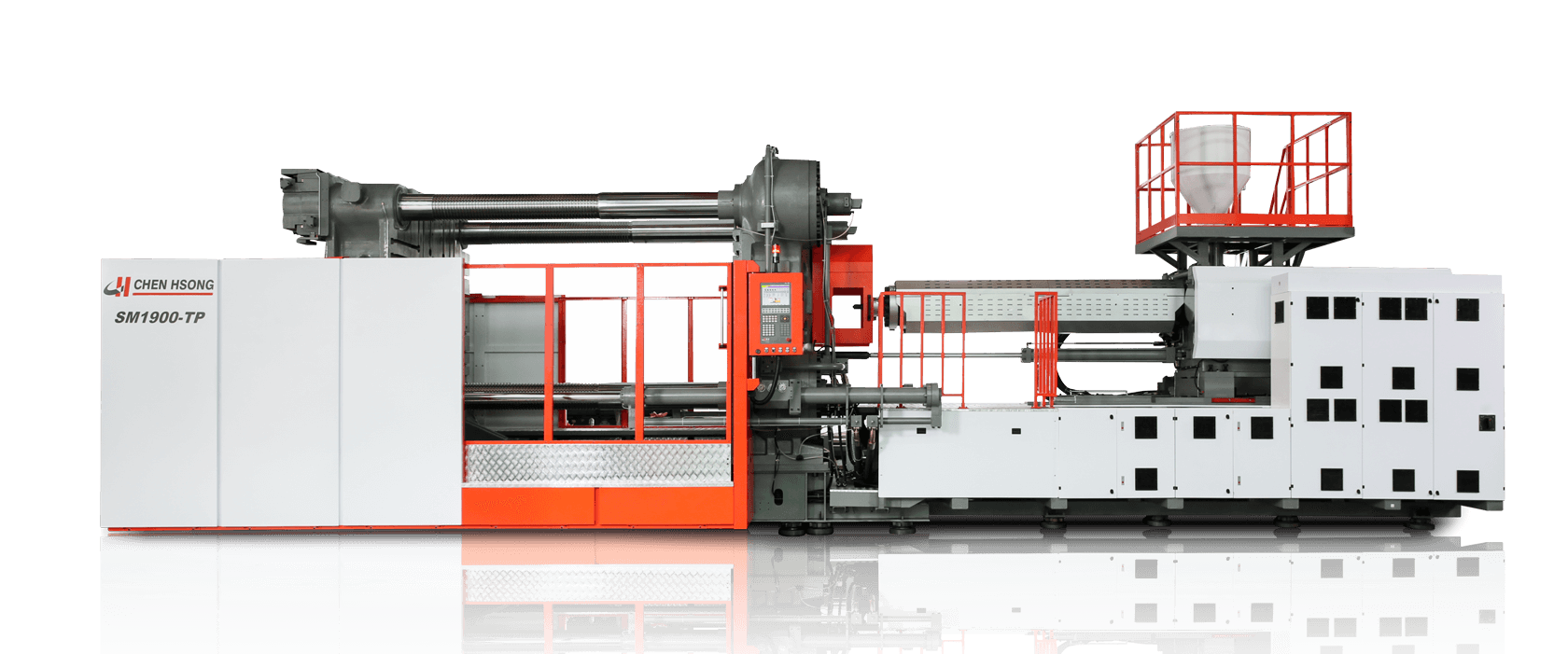

Market leading clients require the highest possible standards in quality and finish. For Siemens, a world leading supplier of medical equipment, the SM2600-TP Two-Platen Injection Molding machine has been the choice for manufacturing HIPS parts for MRI machine casings since 2015.

Applying a clamping force of 2,600 tons with an SVP/2 Servo Drive power pack and controlled by the Nippobatta Ai-12 system, the SM2600-TP Injection Molding machine is able to deliver a shot weight of 11.56kg and yield of over 99% using a C1 Injection Unit in this very demanding application, manufacturing a very large thin-walled component.

Machine Details

Model: SM2600-TP

Model: SM2600-TP

Type: Two-Platen

Year: 2015

Clamping Force: 2,600 tons

Power Pack: SVP/2 Servo-Drive

Controller: Nippobatta Ai-12

Injection Unit: C1

Part Details

Part: Siemens MRI Part

Resin: HIPS

Dimensions: 1,750 X 1,690mm

Product weight: 11.56kg

Yield: 99%+

Op Mode: Semi-automatic

Share this Case Study