Cutting-Edge Two-Platen Technology from Mitsubishi Cooperation

You know very well that Two-Platen injection molding machines are best.

Now learn why OURS are head-and-shoulders above the rest because of ultra-advanced technologies from Mitsubishi!

01

Largest Specs

Smallest Footprint

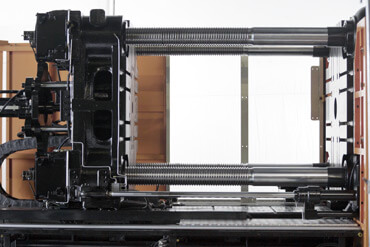

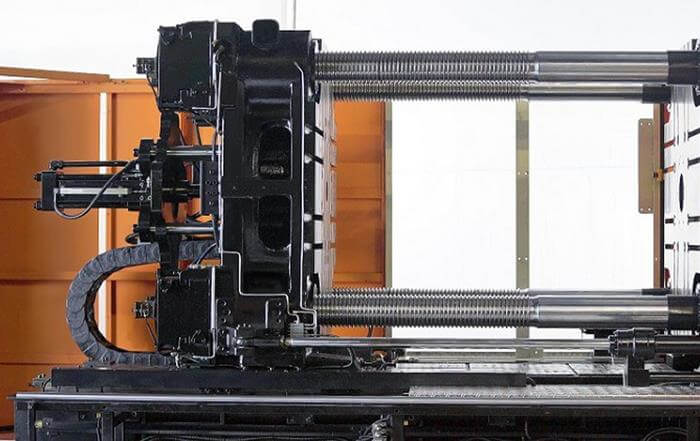

Largest Stroke & Daylight

Advanced two-platen design provides the largest stroke and daylight into the smallest footprint possible!

Japanese Design

High-end Japanese-based designs deliver high precision, high stability, high speed, and ultimate mould protection without any of the traditional compromises.

02

Programmable Controllers

Standards Compliant

Feature Complete

European-standard, IEC 61131-compliant, advanced computer controllers from Beckhoff® and B&R®, employing high-speed digital buses such as EtherCAT™ and PowerLink®, give you the reliability, flexibility, programmability and expandability you require.

One-Stop Flexible Programming

We own the IP (intellectual property) of the controllers on all our machines. You don’t have to go anywhere else for customization or adaptations — we can do it all for you in-house.

03

Efficiency King

Productivity

Clamping speed of up to 750mm/s makes this one of the fastest two-platen designs around. Very short cycle time and high productivity is all but assured.

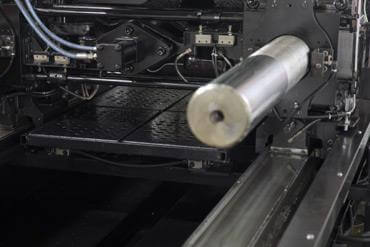

Patented Mechanics

Patented inter-locking mechanism ensures quiet, silky-smooth movements with high precision and repeatability, even when running at top speed.

Energy Saving

SVP/3 servo-drive literally sips electricity! It is unbelievably energy-efficient and friendly to the environment! Saves up to 80% electricity and cooling water consumption.

04

Product Quality

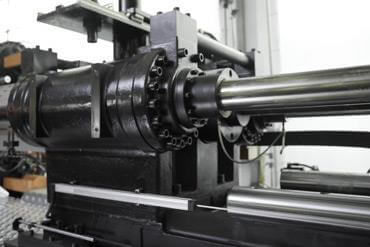

Servo-Drive

SVP/3 (third-generation advanced servo-control) technology has swift responses and superior dynamics.

Advanced hydraulics control technology enables hair-grained motion control with ultra-high precision for demanding applications such as Compressive Moulding. Repeatability within ±0.2% is regularly achieved.

Mould Protection

Achieve the ultimate in mould protection through high-precision and highly-sensitive hydraulics.

05

Modular Flexibility

Mix ‘n Match

Unique modular design from the ground up enables you to choose from a wide variety of possible combinations — 14 clamping units and 29 injection units. One of these must be EXACTLY what you need; why settle for anything less?

Truly GIGANTIC

The largest clamping unit goes up to a whopping 6,500 tons! The largest injection unit packs a shot-weight of 110kg! You can make truly gigantic stuff with these machines!

Y-Injectors

Unique Y-shaped dual-injectors technology allows for further flexibility in mix ‘n match — and a whole new world of possibilities!

Hot Application Areas

Related

K 2019 Flash!!! Day 2 – Attack of the Orange! October 18, 2019 - Green and Low Cost -- Dual-material sandwich production from an MK6 with a 2K side injection unit!

K 2019 Flash!!! Day 2 – Attack of the Orange! October 18, 2019 - Green and Low Cost -- Dual-material sandwich production from an MK6 with a 2K side injection unit!  K 2019 Flash!!! Day 1 – Light – Chen Hsong Lits the SPARK! October 16, 2019 - The new SPARK all-electric wows all.

K 2019 Flash!!! Day 1 – Light – Chen Hsong Lits the SPARK! October 16, 2019 - The new SPARK all-electric wows all.  SPARKS — Chen Hsong Super New Products Carnival 2018 December 17, 2018 - Special event for a special date -- a 12th December of dazzling lights and amazing sounds!

SPARKS — Chen Hsong Super New Products Carnival 2018 December 17, 2018 - Special event for a special date -- a 12th December of dazzling lights and amazing sounds!  Interview with Arçelik CEO Hakan Bulgurlu September 14, 2018 - Chen Hsong and Arçelik in Worldwide Strategic Partnership.

Interview with Arçelik CEO Hakan Bulgurlu September 14, 2018 - Chen Hsong and Arçelik in Worldwide Strategic Partnership.  Adding Vision to LED TV’s July 24, 2018 - Chen Hsong machines for Wybor help make a well-known brand.

Adding Vision to LED TV’s July 24, 2018 - Chen Hsong machines for Wybor help make a well-known brand.  Return of the King in CHINAPLAS 2018: Great Success for Chen Hsong April 29, 2018 - Having completed 60 years and making a mark at CHINAPLAS 2018, Chen Hsong is clearly working towards the next 60 years to greater glory.

Return of the King in CHINAPLAS 2018: Great Success for Chen Hsong April 29, 2018 - Having completed 60 years and making a mark at CHINAPLAS 2018, Chen Hsong is clearly working towards the next 60 years to greater glory.  Strategic Partners for 8 years – U-MHI (Ube Mitsubishi) and Chen Hsong Two-Platens Still Going Strong April 1, 2018 - Chen Hsong is an excellent, reliable partner - exclusive interview with Mr. Koji Kubota, President of Ube Mitsubishi.

Strategic Partners for 8 years – U-MHI (Ube Mitsubishi) and Chen Hsong Two-Platens Still Going Strong April 1, 2018 - Chen Hsong is an excellent, reliable partner - exclusive interview with Mr. Koji Kubota, President of Ube Mitsubishi.  A Modern Day Fairy Tale of Seamless Cooperation August 30, 2017 - Pollino Plast (Serbia) and their Chen Hsong machines.

A Modern Day Fairy Tale of Seamless Cooperation August 30, 2017 - Pollino Plast (Serbia) and their Chen Hsong machines.  Persevere for Excellence, Excel in Innovation! April 27, 2017 - Two-Platen machine with unique "Y-Injectors" technology won yet another award.

Persevere for Excellence, Excel in Innovation! April 27, 2017 - Two-Platen machine with unique "Y-Injectors" technology won yet another award.  Mammoth Machine Delivered to German Processor November 16, 2016 - 3,600-tonne two-platen press and fast tool changes in Germany.

Mammoth Machine Delivered to German Processor November 16, 2016 - 3,600-tonne two-platen press and fast tool changes in Germany.